- Home

- Walk-In Chiller Rooms & Freezers – Manufactured in Turkey, Exported Globally

Walk-In Chiller Rooms & Freezers Made in Turkey

Walk-In Chiller Rooms & Freezers – Manufactured in Turkey, Exported Globally

Walk-in chiller rooms — used in hotels, restaurants, hospitals, and food facilities — are what we build every day. We’ve seen every layout, climate, and challenge. Need a reliable cold storage or freezer room for hot climates? With 30+ years of experience and over 100 global projects, we build and export walk-in chillers and freezers from our factory in Turkey. They’re CE certified, HACCP compliant, and made to perform — even at +50°C.

🏨 Our solutions are actively used by hotels, restaurants, hospitals, and food manufacturers across Africa, the Middle East, Asia, and island countries like the Maldives, Seychelles, and Mauritius.

🧊 Our walk-in chiller units and freezer rooms use high-density polyurethane insulation (PUR, 40–44 kg/m³) to maintain consistent internal temperature and energy efficiency — even under intense usage or harsh climates.

🌍 Whether you’re opening a kitchen in the Maldives, building cold storage in Africa, or supplying a food facility in Asia, our turnkey systems adapt to your layout, climate, and operational needs.

🇹🇷 As a trusted Turkish cold storage provider, we specialize in scalable and customized walk-in solutions. From hotel kitchens to healthcare and food production sites, we engineer systems that support your workflow.

💊 When storing food, drinks, or medicines, even a small temperature shift can cause damage. Our systems keep things clean, cool, and reliable — always.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

✅ Why Choose Us?

Here’s why partners from Africa to Asia choose our Turkey-built cold storage systems:

- 🏷️ Factory-direct pricing

- 📐 Custom dimensions and climate-ready configurations

- 🧼 HACCP-compliant surface finishes

- 📄 CE certified, ready for global export

- ❄️ Tropicalized cooling units – 43°C rated (Bitzer, Daikin, Embraco, Tecumseh)

- 🔧 Easy installation, fast servicing access

- 🚛 End-to-end turnkey solutions – including logistics, install, and commissioning

🔹 Panel Systems & Insulation

Here’s a quick look at how our cold room panel systems come together — like perfectly fitting puzzle pieces. They go up fast, seal in the cold, and stay strong even when the outside air is scorching. We’ve built these in every kind of kitchen, warehouse, and factory you can imagine — and we’ve learned how to make them better with every project.

Feature | Description |

🔲 Type | Sandwich / modular construction |

🧊 Insulation | PUR foam, 40–44 kg/m³ |

🌡️ Thermal Conductivity | ~0.20 W/m·K |

📏 Thickness | 80–100 mm (chillers), 100–120 mm (freezers) |

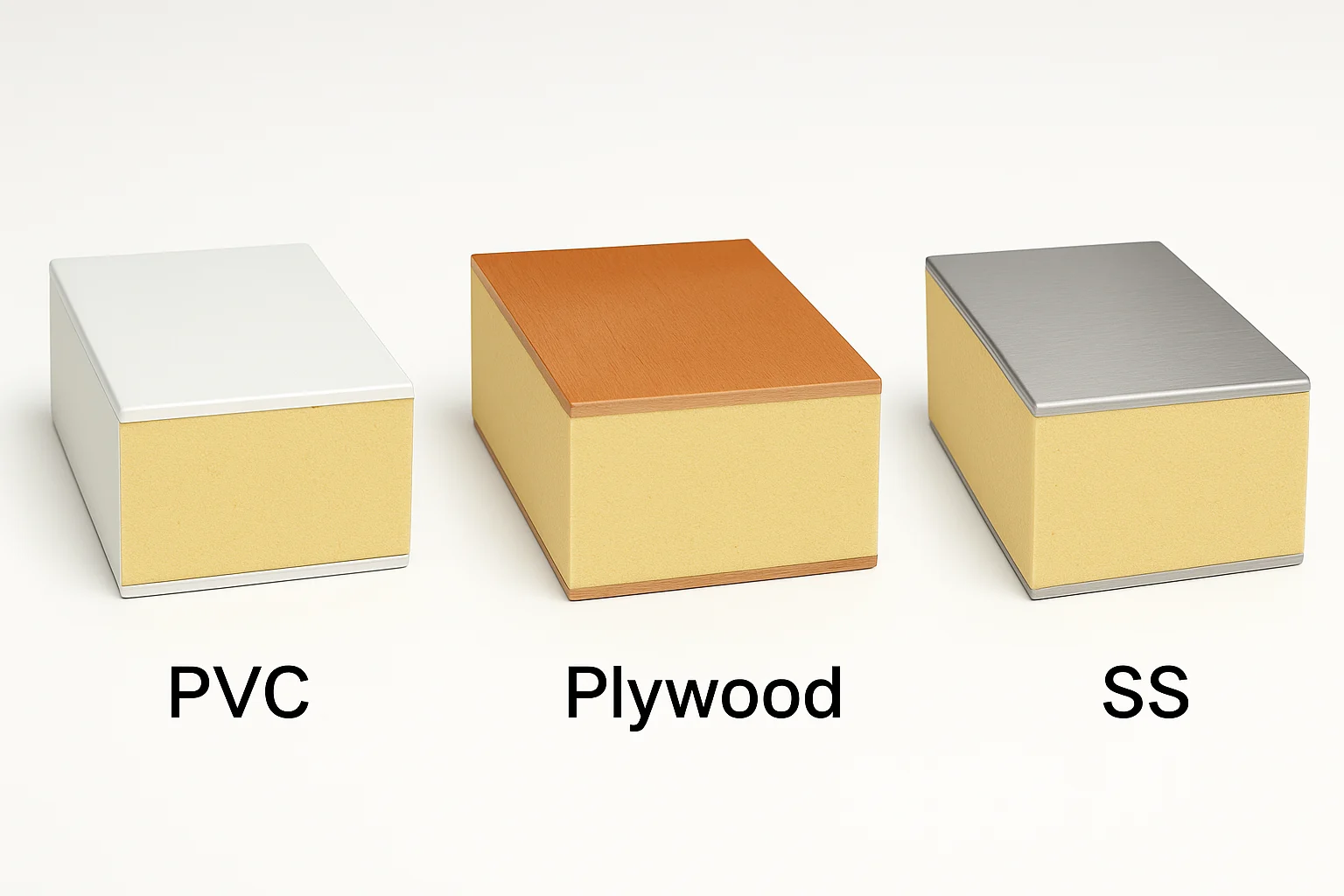

🧽 Finishes | Stainless (AISI 304/316), PVC, galvanized, or aluminum |

🚫 Floors | Plywood, stainless, PVC, or checker aluminum |

🔗 Joint | Cam-lock tongue & groove |

🧼 Corners | Rounded, antibacterial, easy to clean |

🧱 Cold Room Panels – Insulated, Tongue-and-Groove Construction

🪵 Floor Panel Applications – Built for Hygiene and Durability In high-traffic cold rooms, the floor is where wear, water, and workflow collide. That’s why we offer multiple floor panel options to match your operational demands:

- 🟫Plywood Core Panels– A standard option with strong load capacity, finished with either food-grade PVC or stainless steel for light- to medium-duty cold rooms.

- 🧼Non-Slip PVC Coating– Designed for worker safety, this antibacterial surface is ideal for HACCP-compliant kitchens and chilled food storage.

- 🧲Checker Plate Aluminum– Excellent for trolleys, crates, and rugged use; this is a lightweight yet heavy-duty surface with long-term value.

- 🥩Stainless Steel (AISI 304/316)– The top choice for meat, seafood, and industrial food prep areas. High resistance to moisture, corrosion, and disinfectants.

All floor panels integrate seamlessly with our cam-lock tongue-and-groove wall panels, providing a hygienic, flush-finished base that supports safe, efficient operations in any climate.

🔄 Alternative Cold Room Floor Solutions

Not every project requires the same floor structure — and we’ve seen the difference it makes across the world. That’s why we offer several alternate floor installation methods, each with its own operational advantage:

- 🚧Flush-Mounted Ramp Floor Panels– When cold rooms are built directly on level ground, ramp-type floor panels offer easy trolley access without needing civil work.

- 🕳️Recessed Floor Installation (Pit Mounting)– In projects with pre-cast floor pits, we offer recessed panel options that drop inside the concrete base, creating a fully embedded, flush interior.

- 🧱No-Panel Concrete Base– Some industrial users prefer not to use floor panels at all. Instead, we support panel-less cold rooms mounted directly on insulated concrete slabs.

- ❄️Foam or Insulation Layer Under Concrete– Where floor panels are not feasible, thermal insulation can still be provided underneath concrete using rigid insulation boards or spray foam solutions.

Each option is compatible with our modular panel system and carefully matched to your region’s climate, your expected foot or trolley traffic, and your local hygiene regulations.

🧪 Client Insight: A dairy facility in Kenya installed a recessed panel floor system with integrated ramps — reducing loading time by 18% while improving floor hygiene under humid conditions.

🧱 Wall & Ceiling Panel Structure – Holding the Cold, Sealing the Hygiene Our cold room wall and ceiling panels are built to stay strong — on walls or ceilings. Made with the same high-density polyurethane foam (PUR) core, these panels differ by how they’re mounted and supported:

- 🧱Wall Panels– Designed to resist impact, moisture, and thermal shift. Reinforced with cam-lock joints and food-safe coatings like PVC or stainless steel. Rounded corner options for easy cleaning and HACCP compliance.

- 🔼Ceiling Panels– Built to span wide rooms with minimum sag. Reinforced profiles prevent bending, while integrated hangers ensure structural integrity. Available with aluminum, PVC, or antibacterial steel skins.

Every wall and ceiling panel is custom-cut at our Turkish facility, tightly locked with tongue-and-groove joints, and designed to align perfectly with floor panels — ensuring a seamless, sanitary interior.

🔹 Cold Room Door Types

🚪 Hinged Cold Room Doors – Simple, Sealed, Strong Ideal for walk-in chiller room entrances, our hinged doors are insulated, gasket-sealed, and optionally heated for sub-zero use. Durable hardware ensures years of smooth use without sagging or air leakage.

🚪 Sliding Cold Room Doors – Large Openings, Minimal Footprint For busy kitchens, logistic centers or food factories, sliding doors offer space-saving access with secure closure. Produced in Turkey, each unit combines stainless frames and polyurethane cores with thermal break design.

🚪 Monorail Cold Room Doors – Overhead Rail Access Used in meat processing or hanging cold chains, these doors allow products to pass without obstruction. We engineer these for maximum structural load and hygiene performance.

🚪 Flip-Flap Doors – Quick Pass-Through Efficiency Perfect for high-traffic zones, flip-flap (double-action swing) doors allow hands-free movement while maintaining temperature stability. Available with magnetic sealing and soft-close options.

🔹 Cold Room Lighting, Controls & Curtain Accessories

💡 Lighting – Bright, Reliable, Sub-Zero Ready Our LED light kits are IP-rated, condensation-resistant, and long-lasting — ensuring clear visibility and safety.

🌡️ Monitoring Systems – Digital Oversight for Every Degree We provide digital control panels with HACCP logging, remote alarm capability, and temperature traceability.

🚪 PVC Curtains & Air Curtains – Barrier Efficiency Airflow management tools like strip curtains and blower barriers keep cold air inside while allowing frequent door use.

🔩 General Accessories – Finishing Components From shelving to door ramps and internal bumpers, our accessory kit is tailored for every cold room’s operational reality.

🌍 Global Projects,

Trusted Delivery From 5-star hotels in Europe to food depots in East Africa, our systems serve real-world needs. We’re more than a manufacturer — we’re your long-term cold storage partner.

❓ FAQ – Walk-In Cold Rooms & Freezers

What is the difference between a walk-in chiller room and a freezer room?

Chiller rooms usually run between +2°C and +8°C for fresh storage, while freezer rooms go down to -18°C or lower. The insulation thickness and door heating elements differ depending on the target temperature.

How thick should cold room panels be for hot climates like Africa or the Middle East?

For chillers, 80–100 mm panels are enough, while freezers often need 100–120 mm. In tropical zones, thicker panels reduce energy costs and improve stability.

Can walk-in cold rooms be installed without panel floors?

Yes. Many industrial facilities prefer to mount directly on insulated concrete. It’s cheaper but requires proper waterproofing and thermal barriers to avoid condensation.

How do consultants integrate cold rooms into BOQ and MEP drawings?

Cold rooms must be listed with precise panel thickness, cooling capacity, and power load. BOQ integration ensures no surprises in electrical sizing or drainage planning.

What is the expected ROI for investing in Turkey-built cold storage?

On average, clients recover costs in 2–3 years due to energy efficiency, lower logistics costs, and factory-direct pricing. Some hotel projects report savings of 15% compared to European brands.

💬 Real Projects & Client Testimonials – What Our Partners Say