- Home

- Central Type Cooling Devices – Made in Turkey for Cold Chains That Actually Keep Their Cool

Walk-In Chiller Rooms & Freezers Made in Turkey

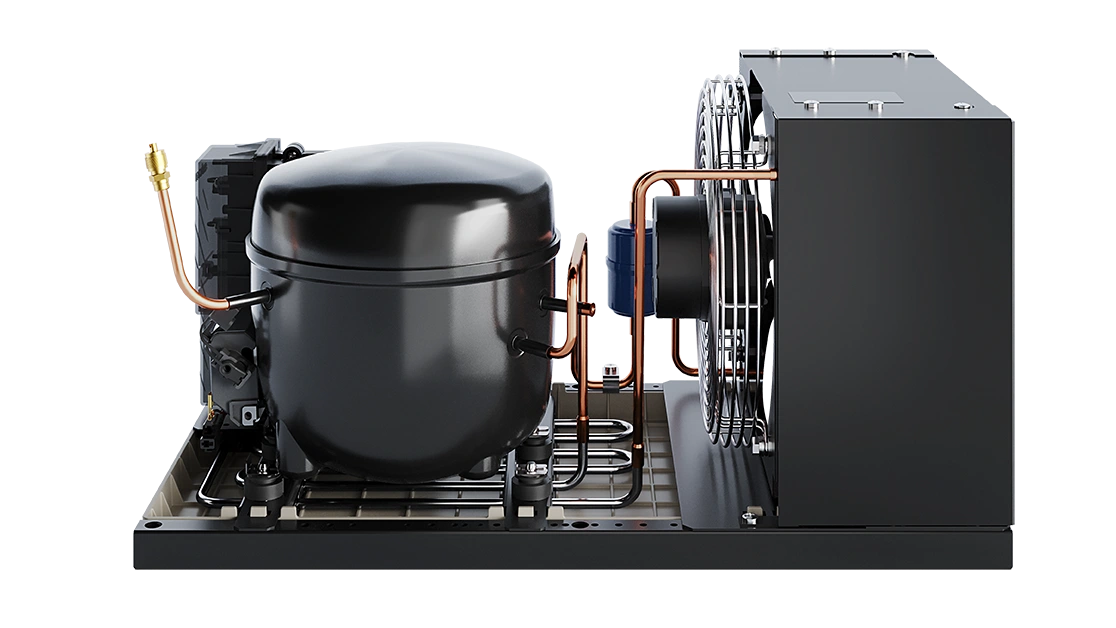

Central Type Cooling Devices – Made in Turkey for Cold Chains That Actually Keep Their Cool

Let’s be honest — when your business starts growing, so does the mess. More rooms. More products. More people yelling “why isn’t this cold yet?” That’s when duct tape won’t cut it anymore.

Enter: central cooling systems.

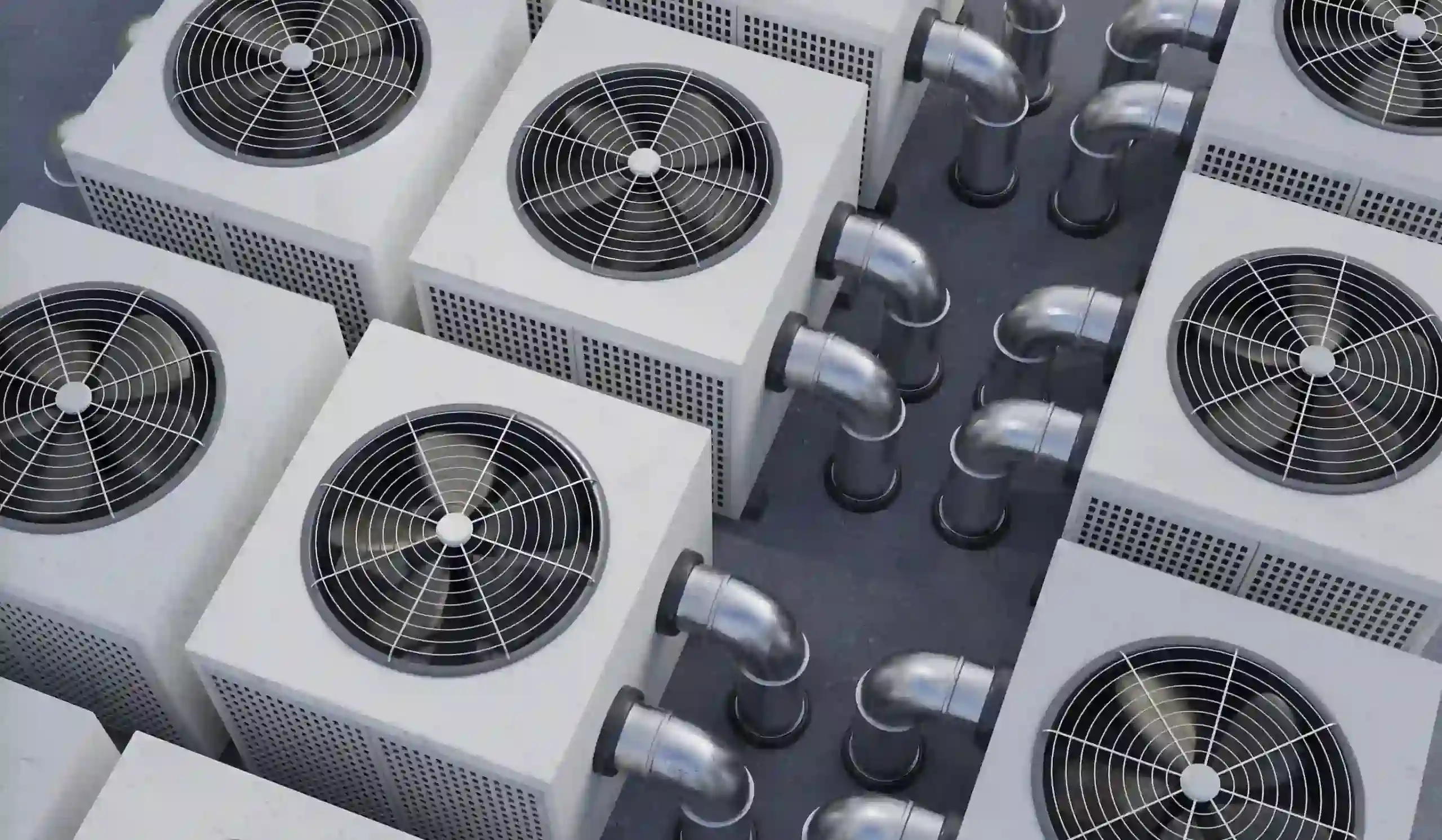

We build these workhorses right here in Turkey, and they don’t flinch. One unit. Multiple rooms. One control hub. That means less noise, fewer headaches, and more cool air exactly where you need it. Whether it’s a meat hub in Lagos, a produce depot in Casablanca, or a pharma warehouse in Doha — these beasts show up, stay steady, and ask nothing in return (well, maybe a routine service check).

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

❄️ Why Central Cooling Hits Different

- 🎛️ One Brain, Many Bodies:Each cold room runs its own temp — freezer here, chiller there — but they’re all fed by one smart system.

- 🚪 Grows With You:Add another room? Change your product range? Just plug in the new zone — the rest keeps humming.

- 💸 Save While Scaling:Less power wasted. Less gear to maintain. Less panic when something goes beep.

- 🧰 One Tech, One Toolbox:No running between five systems. Your service guy will thank you.

- 📡 Controls That Speak Human:Big buttons. Clear data. Alerts that say things like “Hey, this room’s too warm” — not error code #8743.

🇹🇷 Built in Turkey. Built for the Long Haul.

We use top compressors — Bitzer, Frascold, Dorin. Panels built for high-heat zones. Controls pre-wired and labeled (like they should be). Fully CE and HACCP compliant. You don’t get customs surprises — just a solid crate and even better support.

We’ve shipped these to 25+ countries — and counting.

🏢 Where Central Units Make Life Easier

Distribution centers juggling multiple temp zones • Factories that need both chilled prep and frozen storage • Hotel kitchens with complex foodservice workflows • Export hubs with rotating SKUs • Cold logistics depots where loading bays never sleep

❓ FAQ – Central Cooling Systems

How do central cooling systems actually save energy compared to multiple split units?

By sharing compressor capacity across several rooms, the system avoids over-sizing. That means less idle running, 15–25% lower electricity use, and smoother temperature stability.

Can I expand later without replacing the whole system?

Yes. Central systems are modular. Adding a new cold room is just about extending pipework and updating controls — no need for a second full unit.

What kind of maintenance do these systems need?

Routine oil checks, filter cleaning, and monitoring compressor hours. Because it’s one hub, servicing is faster and often cheaper than running several separate units.

Do central systems handle power cuts or unstable grids?

We can equip them with dual-compressor redundancy, automatic restart, and compatibility with backup generators — features designed for Africa and Gulf regions.

What’s the typical lifespan of a central system built in Turkey?

With proper care, 12–15 years is common. Many facilities still run them beyond that, especially when parts are replaced on schedule.

💬 Real Projects & Client Testimonials – What Our Partners Say