- Home

- Walk-in Chiller Room Components – Engineered in Turkey

Walk-In Chiller Rooms & Freezers Made in Turkey

Walk-in Chiller Room Components – Engineered in Turkey

You’ve got the cooling system figured out — great. But without the right components supporting it, even the best compressor is just… a really expensive metal box. The truth? A cold room is only as strong as the pieces holding it together. And that’s where our job begins.

We manufacture cold room components in Turkey that do more than just fit — they function. They’re designed to make your cold room faster to install, easier to clean, safer to use, and tougher than whatever environment you throw them in. And yes, we’ve tested them. Not just in labs, but in chaotic kitchens, warehouse hellscapes, and sunny loading docks where the heat laughs at your plans.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

🧩 Cold Room Panels – Insulated, Tongue-and-Groove Construction

Panels are the bones of your cold room. And if they’re not solid, nothing else matters. We produce high-density, insulated sandwich panels using PUR foam (40–44 kg/m³) right here in Turkey.

- 🔗 Tongue & Groove, Cam-Lock System:Fast assembly, airtight joinery. Panels lock in tight and don’t let heat sneak through the cracks.

- 📏 Thickness Matters:Available in 80–100 mm for chillers and up to 150 mm for freezers.

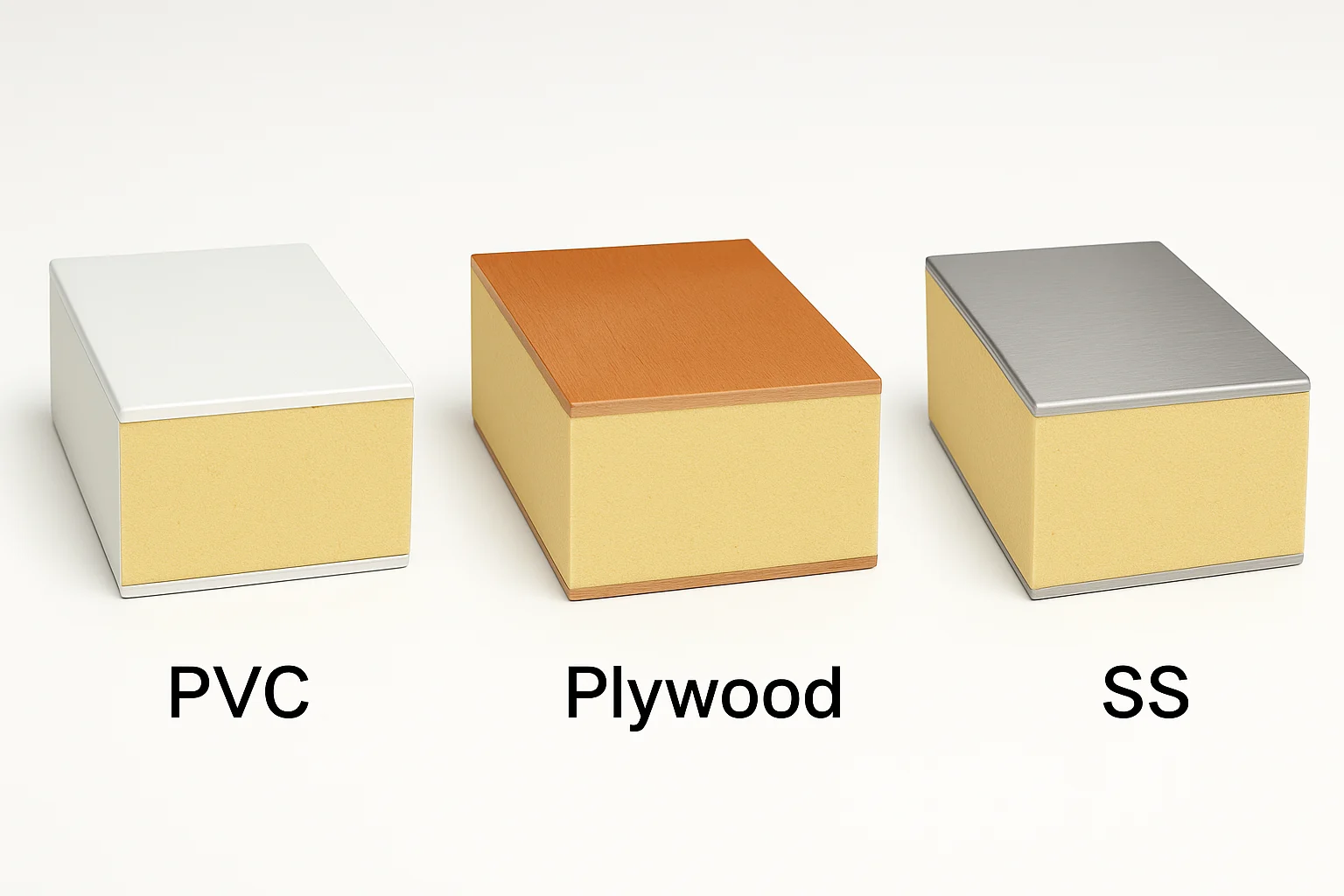

- 🧽 Surface Options:Stainless steel (AISI 304/316), antibacterial PVC, galvanized sheet, or food-grade aluminum — all smooth, all easy to clean.

- 💧 No Funky Corners:Rounded internal profiles prevent bacteria buildup and make sanitation fast. And who doesn’t love fewer scrubbing sessions?

- 🌡️ Thermal Conductivity:Engineered to maintain internal temps with minimal energy waste (~0.20 W/m·K).

These panels are modular, customizable, and engineered to keep your cold where it belongs. Plus? They look sharp.

Customer Insight: One of our partners in Accra, Ghana shared that the quick-snap cam-lock system saved his crew 2 full days on installation time — and kept labor costs down by 15%.

🚪 Cold Room Doors – Swing, Sliding & Flip-Flap Types

A door that doesn’t seal right is more than annoying — it’s a liability. That’s why we build doors that know how to shut up and stay shut.

- 🚪 Hinged Doors:Perfect for daily use with integrated locking, gasket seals, and anti-freeze heaters for freezer units.

- ➡️ Sliding Doors:Save space, reduce air exchange. Ideal for larger facilities or side access zones.

- 🚪 Flip-Flap Doors:Flexible PVC types that allow quick, hands-free movement — common in fast-paced kitchens, production zones, or retail coolers.

- 🛠️ Build Options:Each door includes high-durability hardware, magnetic gaskets, and manual or automatic closing systems. Because yes — sometimes it’s the little things that save the big picture.

Built in Turkey. Field-tested in the real world. And yes, every unit ships with its own toolkit and mounting manual that doesn’t read like a physics textbook.

Real-World Story: A hotel in Jordan reported that the soft-swing flip-flap doors helped reduce kitchen traffic bottlenecks during breakfast service by 40%. Now that’s workflow.

🔩 Cold Room Accessories – Shelving, Lighting, Safety Components

You wouldn’t drive a car with no seatbelts or headlights. So don’t settle for a cold room with bare walls.

- 📚 Shelving Systems:Adjustable, corrosion-resistant, and load-tested. We offer plastic-coated steel, anodized aluminum, and stainless options — for dry goods, meat, dairy, or whatever else you’re stacking high.

- 💡 Lighting:Waterproof LED lighting kits that mount cleanly and keep the room bright. Cool color temp, low power usage, and no dark corners.

- 🚨 Safety Gear:Panic bars, internal release handles, and motion sensors. Because accidents don’t announce themselves.

- 🧼 Hygiene Add-ons:Antibacterial gaskets, corner protections, and sloped thresholds — to make your cleaning team smile. Or at least not swear at you.

All our accessories are modular, easily mountable, and stocked with replacement parts that don’t take 12 weeks to arrive.

Installer Note: A contractor in Morocco told us our modular shelf kits saved 3 hours on each installation — “It just clicks into place. No drills. No curse words.”

🇹🇷 Why Choose Components Made in Turkey?

Because we’ve been building these systems for over 30 years. We’re not guessing what works — we know. Our components are used in hotels in Jordan, bakeries in Algeria, dairies in the Balkans, and container ports in West Africa.

They’re CE-marked, HACCP-compliant, and designed for environments that don’t care about your excuses — just your uptime.

And yes, we speak international logistics fluently. Real-time support, real documents, and people who follow through.

❓ FAQs – Questions We Hear Often

Can I mix your panels with an existing cold room structure?

Yes. Panels are modular and interlock with cam-lock joints, so they integrate with most standard builds — new or retrofit.

Do the doors handle heavy-duty use in industrial zones?

Absolutely. Hinged, sliding, and flip-flap models are tested for thousands of daily cycles. For freezers, heated frames stop frost buildup.

How do accessories improve workflow beyond storage?

Shelving systems prevent clutter, LED lighting improves inspection speed, and safety handles cut accident risks. Together, they reduce downtime by up to 20%.

What surface finishes work best for food vs pharma vs industrial use?

Food prep zones prefer stainless steel or PVC for hygiene. Pharma often chooses antibacterial PVC. Industrial depots sometimes go with galvanized finishes for durability.

Can components handle extreme climates?

Yes. Panels and doors are tested for ambient heat up to +45°C, with thermal conductivity engineered at ~0.20 W/m·K to maintain efficiency in tropical and desert zones.

💬 Real Projects & Client Testimonials – What Our Partners Say