- Home

- Dough Kneaders & Spiral Mixers – Turkey-Built Systems for High-Output Commercial & Industrial Kitchens

Cooking Equipments

Dough Kneaders & Spiral Mixers – Turkey-Built Systems for High-Output Commercial & Industrial Kitchens

Commercial Bakery Equipment Made in Turkey

Dough Kneaders & Spiral Mixers – Turkey-Built Systems for High-Output Commercial & Industrial Kitchens

📌Lessons Learned from Global Bakery Projects

We walked into a bakery kitchen in Nairobi where the procurement manager whispered to us: “The recipe is right, but the mixer just gave up before the dough did.” That scene repeat more than once, and it show us something real—when the spiral mixer fails, the entire commercial kitchen workflow collapses. In our turnkey projects across Africa, the Middle East, and Europe, this lesson keep coming back. You don’t just need a machine, you need an engine for your dough program.

In Muscat, a consultant told us during a site audit: “Layout is fine, BOQ looks fine, but if your mixer shakes or overheats, my client lose money.” He right. That’s why we never just drop catalog models—we engineer mixers built in Turkey that actually match the load list, MEP specs, and BOQ priorities. This ain’t about a box, it about a system that keep staff safe and service steady.

From Warsaw cloud bakeries to resort FOH pastry bars in Bodrum, we seen how contractors, designers, and F&B teamsall struggle when mixers don’t fit their workflow. That’s why every unit we deliver—whether 30kg or 200kg capacity—comes tuned for staff flow, power line, and hygiene rules. Manufactured in Turkey, exported worldwide, these spiral mixers don’t just knead dough, they protect your service line and save you from chaos.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

Product Line Overview – Technical Table

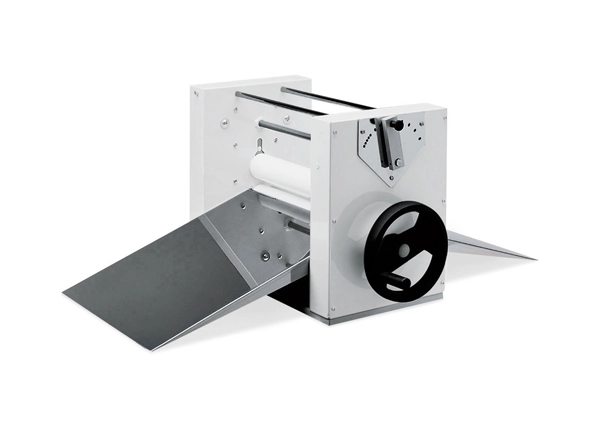

Model | Flour Capacity | Dough Capacity | Bowl Volume | Dimensions (mm) | Power / Voltage | Material |

SM-30X | 20–30 kg | 30–45 kg | ~75 L | 580 × 900 × 1100 | 2.2 kW • 400V 3N 50/60Hz | AISI 304 (316 opt.) |

SM-50X | 35–50 kg | 50–80 kg | ~120 L | 700 × 1100 × 1250 | 3.0 kW • 400V 3N 50/60Hz | AISI 304 (316 opt.) |

SP-80K | 80 kg | 130 kg | ~180 L | 1341 × 1748 × 1385 | 9.5–10 kW • 400V 3N | AISI 304 (316 opt.) |

SP-200K | 125 kg | 200 kg | ~280 L | 1520 × 1946 × 1748 | 9.5–10 kW • 400V 3N | AISI 304 (316 opt.) |

👉 All models ship with safety grids, emergency stop, and bowl/spiral guards; industrial kitchen variants available with IP-rated panels.

Build, Safety & Installation

We don’t drop a crate and disappear—we align power and space so the mix line actually run smooth.

- Power: 400V 3N (50/60Hz); smaller sites 220–240V single-phase adapter kits on request.

- Amp draw: 10–24A depending on model; RCD/RCBO recommended.

- Docs: CAD/DWG cut-outs, cable route, anchoring map.

- Commissioning: Remote or on-site; operator training cheat-sheet.

Durability & Build Quality

Heavy frames, reinforced gear sets, and serviceable bearings—because dough don’t forgive flex.

- Cycle tests: 15,000–20,000 load cycles.

- Lifecycle: 7–9 years in daily use (3-shift bakeries seen even more).

- Materials: Food-contact parts in AISI 304, optional AISI 316 for humid/marine.

Hygiene & Safety (CE/HACCP)

No sharp edges, no dirt traps, no drama.

- CE interlocks on guards; auto-stop if grid open.

- Rounded corners; easy-wipe seams; HACCP-friendly labeling.

- Optional IP54 control box for splashy prep rooms.

🎯Why Choose Us & Key Advantages

You ain’t buying metal; you buying throughput. We bundle design logic with hardware so the commercial kitchenstays predictable in peak.

- Turkey-built at scale; modular spare strategy; fast export.

- Dual-speed torque for strong dough and high hydration pizza.

- Low vibration for FOH pastry bars; noise stay low, guests stay happy.

- BOQ-matched specs so consultants don’t fight surprises on site.

- Energy-aware drives; less idle, more batch—real ROI.

📦 Procurement & BOQ Integration

We speak the same sheet as your spec team.

- BOQ mapping with model-to-output tables.

- MEP schedules: load list, breaker size, cable section.

- Submittals: CE/HACCP, food-contact declarations, exploded views.

🔍 Comparison Guide – Spiral vs Planetary vs Fork

Feature | Spiral Mixer | Planetary Mixer | Fork Mixer |

Best For | Bread & pizza dough, high hydration | Creams, batters, specialty doughs | Artisan dough, delicate mixes |

Strengths | Strong gluten development, fast mix | Versatility for pastry & confectionary | Gentle action, preserves dough air |

Limitations | Limited use beyond dough | Not ideal for strong bread doughs | Slower, lower capacity |

Typical Location | Industrial & commercial kitchens | Pastry kitchens, hotels, restaurants | Artisan bakeries, specialty kitchens |

📐 Design & Workflow Integration

If the mixer is 8 meters from cold room, dough temp creep will bite you—it really do.

- Place mixers near cold storage; target dough temp stays on spec.

- Keep 1.5 m perimeter clear; trolley turns without collisions.

- Separate mixers from ovens to reduce ambient heat rise.

- Visual line of sight between scale table → mixer → divider.

🏨 Banquet & Buffet Operations – Handling Peak Loads

Hood type dishwashers carry banquets when plate return spikes above 1,000 per hour. Pass-through ergonomics keep the rack stream moving so chefs reset buffets faster and guests never feel the backlog. In an Istanbul conference center, switching to a hood line cut post-event reset times by 25% and reduced dish return pile-ups during peak service.

- Handles 1,000–1,400 plates/hour with proper rack staging

- Ergonomic hood lift lowers strain; fewer fatigue complaints

- Pass-through layout keeps banquets on schedule without extra staff

🧩 OS&E Integration

We bundle tools so operators don’t improvise with the wrong spatula mid-rush.

- Bowl trolleys & lifters, stainless scrapers, portion cutters.

- Replacement bowls, guards, and timing labels.

- Integration with proofing cabinets and dough sheeters for straight-through flow.

Advanced Project Add-Ons

Export & Logistics (Crating That Survives)

Global projects demand resilient packing and logistics.

- Foam & corner guards protect against forklift damage.

- Tilt sensors ensure safe handling during shipping.

- IP-safe wrapping keeps units dry in humid regions.

Model Selection by Output

Sizing matters; wrong pick means wasted hours.

- SM-30X → 50–150 loaves/day. Ideal for small hotel bakeries or FOH pastry labs running breakfast or light production.

- SM-50X → 150–400/day. Balanced choice for mid-size commercial kitchens with continuous bread & pizza flow.

- SP-80K → 400–900/day. Suitable for industrial prep lines or resort commissaries serving multiple outlets.

- SP-200K → 900+ loaves/day. Built for large-scale industrial kitchens, central bakeries, and export-driven factories.

🌍 Where They Work Best – Global Scenarios

- Nairobi – Central bakery in a hotel: SM-50X on breakfast shift, SP-80K on banquet prep; staff report 16% faster proofing turn because mixing windows got tighter.

- Muscat – Resort pizza bar (FOH): Low-noise SM-30X tucked behind marble; guests see show, not hear the motor.

- Warsaw – Cloud bakery: SP-200K handles night batch; morning crews don’t wait—it start and it go.

🛠️ Cleaning & Maintenance

Clean gear live longer—sounds obvious, still it get skipped when rush hit.

- Daily: Bowl/spiral rinse with mild detergent; wipe control face.

- Weekly: Belt tension & grease points check.

- Quarterly: Bearing inspection; electrical terminal re-torque.

🔄 Continuous Flow – Pass-Through Efficiency

Unlike compact units, hood models keep a straight rack path that eliminates zig-zag walking and waiting. At a Dubai resort, optimizing the pass-through corridor shortened staff travel distance by 22% and improved tray turnaround by 15 minutes per service window. Procurement teams also found training simpler because the flow is predictable.

- Constant rack movement minimizes queueing at dish return

- 20–22% shorter staff travel in field tests

- Safer aisles with fewer cross-traffic incidents

💰Energy Cost Analysis & ROI

- Dual-speed drives → Reduce idle by 12–18%, meaning less wasted energy during slow prep hours.

- Case Study – Istanbul hotel bakery → After switching to dual-speed mixers, energy bills dropped by ~18% in 6 months, while output consistency improved.

- ROI window → For heavy-use kitchens, payback is usually visible within 12–18 months thanks to lower energy bills + less downtime.

🌐Consultant Insights & Case Studies

Extra insights and field results close the loop between specs and reality.

- Case Study – Dubai luxury hotel → Installed SP-200K units across two outlets, downtime reduced by 22% in first quarter.

- Consultant Feedback – Kenya → “When mixers matched MEP drawings exactly, staff saved 30 minutes daily just on workflow alignment.”

- Case Study – Athens resort → Hybrid use of SM-50X and SP-80K gave 12% higher efficiency in pizza and bread prep.

❓ Frequently Asked Questions (FAQ)

How big spiral mixer do I need for a hotel bakery?

Pick by daily output and hydration: most commercial kitchen hotels do fine with 50–80 kg dough capacity per shift segment.

What’s the difference between spiral and planetary mixers?

Spiral kneads bread/pizza dough better; planetary is for creams/batters; they ain’t substitutes.

Do I need 3-phase power for industrial spiral mixers?

Yes for medium/large units; compact lines can run single-phase adapters, but torque drop may show.

Can you align models to our BOQ and MEP drawings?

Yes—send layout and load list; we return submittals, breaker sizes, and cut-outs.

5. What’s the typical lifecycle and service schedule?

7–9 years with basic care; daily wipe, weekly tension check, quarterly bearing review.

💬 Real Projects & Client Testimonials – What Our Partners Say