- Home

- Walk-In Blast Chiller & Freezer Rooms for Rapid Temperature Reduction

Walk-In Chiller Rooms & Freezers Made in Turkey

Walk-In Blast Chiller & Freezer Rooms for Rapid Temperature Reduction

When timing’s tight and the heat is high, there’s no space for “gradual.” Freshness fades fast — and your cold room needs to move faster. Blast freezing is more than just cooling food. It’s locking in texture, color, safety, and shelf life — all in the brief window before “fresh” turns into “waste.”

We build blast chiller and freezer rooms in Turkey for operations that live on the edge of precision. Whether it’s seafood just off the boat, pastries hot from the oven, or bulk meals that need to hold till tomorrow, our systems hit hard, cool fast, and recover like pros — shift after shift, tray after tray.

Because in your kitchen, freshness has a deadline. And you don’t get extensions.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

🧊 What Real Blast Chillers Have to Deliver

. 🚀Rapid Core Cooling:Drop food temps from +70°C to -18°C in hours — no delays, no guessing.

· 💨 Balanced Air Circulation: High-speed fans, no burn zones. Cold air reaches edge to center, fast and evenly.

· 🚪 Designed for Rush Hour: Large doors, reinforced floors, zero obstructions. Because loading doesn’t slow down.

· 🧠 Controls That Speak Your Language: Easy interfaces. Reliable alarms. Settings you can read at 5 a.m. with one eye open.

· 🧱 Insulation That Works Under Pressure: 120–150 mm thick PUR panels that stay cold, no matter what’s outside.

· 🦠 Hygiene Without Hassle: No bacteria, no biofilm. Chill fast, clean faster — food stays safe, always.

🌍 Who Trusts Our Blast Freezers

We build for the ones who can’t afford slow:

. 🧊 Meat processors racing to seal in freshness

· 🐟 Seafood teams freezing the catch before it changes

· 🍞 Bakeries protecting the integrity of every delicate crust

· 🥘 High-volume caterers cooling food for tomorrow’s service

· 🍱 Ready-meal producers banking on shelf life

📊 Construction Snapshot (Built for Quick Freeze)

Feature | Description |

🔲 Type | Extra-thick modular build – 120–150 mm PUR insulation |

🧊 Insulation | High-density rigid foam (44+ kg/m³) |

📏 Dimensions | Custom sizing for high-volume, fast-loading needs |

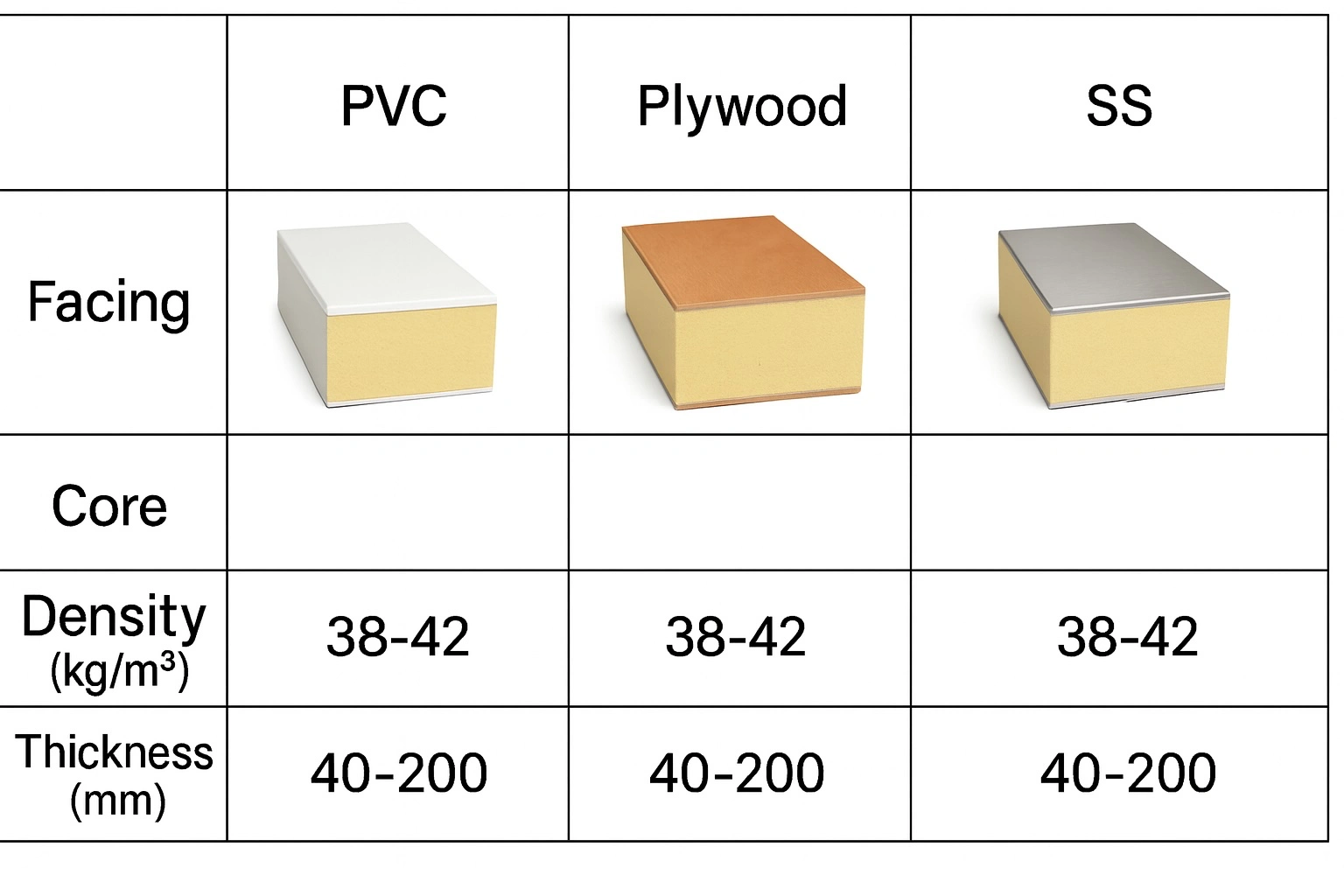

🧽 Finishes | Food-grade stainless or hygienic PVC – fast wipe-downs |

🚪 Doors | Swing/sliding – reinforced, gasket-sealed |

🔗 Joints | Cam-lock – seals in cold, keeps out airflow leaks |

🧼 Drainage | Sloped floors, central drains – cleanup is one pass |

💡 Accessories Built for Momentum:

- LED lights that brighten with zero heat spill

- Air curtains and smart control units that react instantly

- Stainless racks for fast in/out movement

- Sensor-ready wiring for smart alerts and defrost timing

📋 Why Our Blast Rooms Deliver Under Pressure

. 🇹🇷 Made in Turkey – CE-certified, globally installed, kitchen-proven

· 📊 Capacity from 500 kg to 10+ tons/day – scale it your way

· 🧾 Delivered with export docs, setup manuals, and install-ready panels

· ❄️ Compatible with Bitzer, Embraco, Daikin systems – world-class cooling brands

· 🛠️ Remote monitoring, defrost cycle options, and safety backups available

❓ FAQ – Waste & Grease Solutions

Why are grease traps important?

They block fats, preventing clogs and fines. Best grease trap solution for hotels and catering hubs.

How much waste can disposal units handle?

From 150 to 300 kg/hr depending on model. Ideal for commercial kitchens with continuous prep.

Are units HACCP certified?

Yes, all models include CE/HACCP packs.

Can systems be retrofitted?

Yes, modular design fits existing kitchens without heavy construction.

Do you provide OS&E accessories?

Yes, bins and trolleys are part of supply, delivered turnkey for industrial kitchens.

💬 Real Projects & Client Testimonials – What Our Partners Say