- Home

- Cold Room Cooling Units Manufacturer in Turkey

Walk-In Chiller Rooms & Freezers Made in Turkey

Cold Room Cooling Units Manufacturer in Turkey

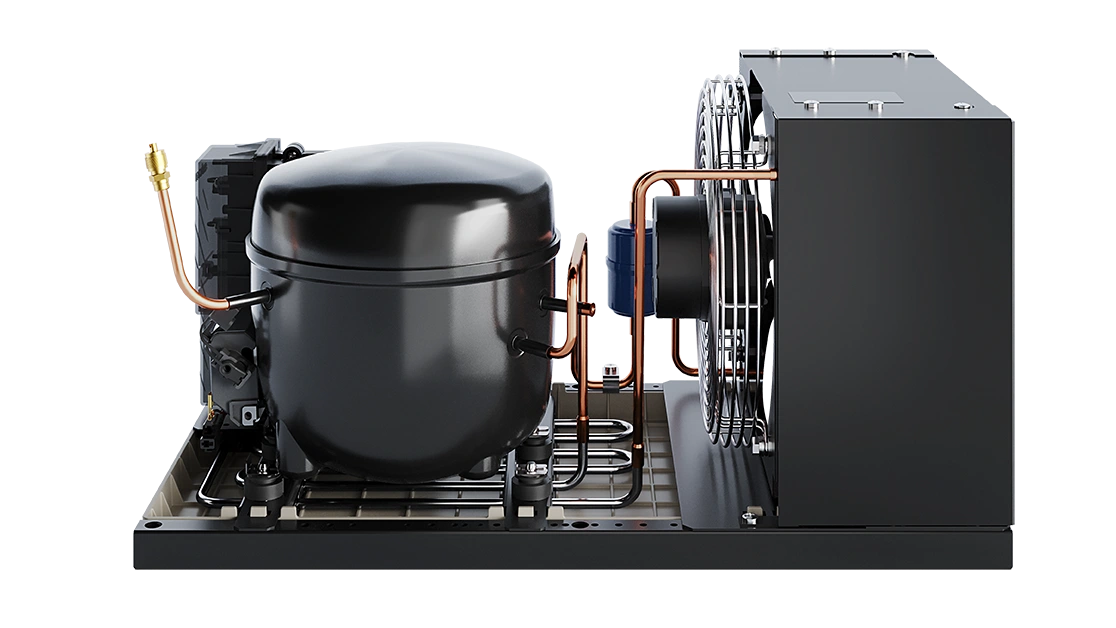

As a cold room cooling units manufacturer, we design and produce cooling systems for cold rooms and freezer rooms used in commercial and industrial kitchen projects. Let’s be honest — when your cooling fails, everything else is just noise. Whether you’re setting up a blast freezer near the docks in Lagos, or assembling a walk-in chiller in a hotel kitchen in Jakarta — if the temperature’s not right, the whole system’s down. And that’s not something you can afford to gamble on.

That’s why we don’t just “make” cooling units in Turkey. We build them like someone’s reputation depends on them — because it usually does. These units aren’t just metal and gas; they’re workhorses. Quiet, steady, tough as nails. Built for the real world — the one with heatwaves, voltage drops, and timelines tighter than a delivery van in traffic.

We build for people who can’t hit pause. Who don’t have time to reboot. Who need the cold to be cold, every single time. And we ship it everywhere — from field kitchens in Africa to distribution centers in the Gulf.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

❄️ Cold Room Cooling Units Manufacturer in Turkey for Global Projects

- 🌞 Heat-Proof by Design:Tropical? Bring it on. Our cooling systems keep things steady at up to +43°C ambient. No stress, no drift — just reliable chill.

- ⚡ Recovery That Actually Recovers:Doors open and close a hundred times? Bulk stock coming in? No worries. Our systems bounce back fast so your product doesn’t suffer.

- 🔇 Quiet Where It Counts:In the middle of a dinner rush or food prep marathon, you’ll barely hear it running — but you’ll feel the difference in every degree.

- 💡 Energy Smart, Not Energy Hungry:We don’t believe in trade-offs. Efficient components. Smarter flow. Lower bills, same performance.

- 🌍 Built for Borders:CE marked and HACCP aligned, with documentation prepared in line with CE conformity requirements, ensuring smooth customs clearance and export-ready delivery.

🌍 Cold Room Cooling Units Manufacturer in Turkey for Global Projects

You’ll find our systems chilling everything from fruit crates in Mauritania to gelato tubs in Oman. Not by accident — but because they’re built right.

Made in Turkey with compressors and components you actually trust — Bitzer, Embraco, Tecumseh, Danfoss. And backed by people who pick up the phone.

This isn’t about selling you cooling. It’s about helping you stay cold — even when the heat is relentless.

As a cold room cooling units manufacturer, we support hotel kitchens, central kitchens, and food processing facilities with project-based cooling solutions.

🔧 Cold & Freezer Room Cooling Systems We Manufacture in Turkey

Best for tight setups or medium walk-ins. Easy install. Minimal noise. Just enough power without overkill.

- 🧰 Semi-Hermetic Cooling Units for Cold Rooms

Heavy-duty cooling for big storage needs. Durable, repairable, and up for the long haul. - 🏭 Central Cooling Systems

Run multiple cold rooms from one smart core. Great for big kitchens, warehouses, or multi-zone setups. - 💧 Air & Water-Cooled Units

Coastal? Desert? On a hill with funky grid voltage? We’ve got the cooling system that matches your conditions.

Choosing a reliable cold room cooling units manufacturer is critical for long-term performance, compliance, and operational continuity.

❓ FAQ – Cold & Freezer Room Cooling Units

How do I choose between hermetic, semi-hermetic, and central cooling units?

Hermetic units suit small to medium walk-ins, semi-hermetic options are better for heavy-duty and repairable setups, while central systems power multiple rooms at once — ideal for warehouses or large kitchens.

Do Turkish-built cooling units handle unstable electricity common in some African regions?

Yes. Units can be equipped with voltage stabilizers and soft starters, ensuring stable cooling performance even with grid fluctuations or generator use.

How do air-cooled and water-cooled systems differ in performance?

Air-cooled units are easier to install and maintain, while water-cooled systems perform better in extremely hot climates or where ambient air temperature frequently exceeds 40°C.

What are the typical maintenance needs for these cooling units?

Monthly checks of filters, refrigerant pressure, and condenser cleaning keep the system efficient. Semi-hermetic units also allow part replacements, extending lifespan.

How do efficient cooling systems reduce operating costs for hotels or food processors?

By optimizing airflow and using branded compressors (Bitzer, Embraco, Tecumseh, Danfoss), energy bills can drop 15–20% compared to outdated units, while protecting product quality.

💬 Real Projects & Client Testimonials – What Our Partners Say