- Home

- Cold Room Doors – Swing, Sliding & Flip-Flap Types

Walk-In Chiller Rooms & Freezers Made in Turkey

Cold Room Doors – Swing, Sliding & Flip-Flap Types

You can have the best insulation, perfect cooling unit, and premium layout — but if your cold room door fails, you’re letting heat in, money out, and performance slide. That’s why we treat cold room doors not as afterthoughts, but as precision-built components that make or break your cold chain.

From our factory in Turkey, we manufacture walk-in chiller and freezer doors that are trusted by clients across Africa, the Middle East, Europe, and island nations. These doors aren’t just built to seal — they’re built to endure. High-traffic, high-humidity, fast-paced operations? Bring it on. Our doors swing, slide, and flex with your daily rhythm — literally.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

🚪 Hinged Doors – Everyday Durability, Sealed with Trust

Let’s start with the classic: the hinged cold room door. It’s the workhorse of walk-ins and the favorite of countless chefs, warehouse staff, and facility managers. But what sets ours apart?

- 🧊 Gasket-Sealed Performance:Our magnetic gaskets lock tight and stay that way — even after thousands of openings.

- 🔥 Anti-Freeze Heaters (For Freezers): No more frozen shut doors. Our built-in frame heaters ensure functionality even in sub-zero environments.

- 🔐 Lock Systems:Built-in security locks and interior emergency release handles offer both control and safety.

- 📏 Custom Sizes:Whether it’s for a tight hotel pantry or an industrial meat facility, we build to fit.

💬 “We installed your hinged doors at a seafood facility in Nigeria. A year in — zero warping, zero gasket wear. Just performance.” – Regional Contractor, Lagos

➡️ Sliding Doors – When Space Is Tight, But Efficiency Can’t Wait

When your cold room sits in a corridor, beside shelving, or in the middle of a busy operation, every centimeter counts. Sliding doors offer seamless access without swinging into tight paths.

- ⚙️ Smooth Rail Systems:Our stainless steel or anodized aluminum track systems glide open with ease — even when installed outside in humid zones.

- ❄️ Thermal Break Construction:Frame and panel integration minimizes thermal bridging, which means less condensation and better energy savings.

- 🔩 Soft-Close Dampers (Optional):Because nobody wants doors slamming next to raw food or delicate stock.

📦 Case study: In a bakery chain in Cairo, sliding doors reduced cold air loss by 28% compared to their older swing systems — resulting in 12% energy savings in the first quarter.

🚪 Flip-Flap Doors – Speed, Safety, and Simplicity

Sometimes, you just need to move. No hands. No handles. No hesitation. Flip-flap doors are the unsung heroes of fast-paced food factories, catering kitchens, and logistics corridors.

- 💨 Dual-Layer Flexible PVC:Our food-grade PVC offers smooth opening with memory rebound — transparent, soft-edged, and safe.

- 👟 Walk or Drive-Through Ready:With options reinforced for trolley and pallet jack traffic.

- 🌡️ Optional Strip Curtains:Combine with air curtains or overlapping flaps for even better energy retention.

📍 Used by a cruise kitchen in the Mediterranean where constant motion and temperature integrity mattered most.

🔧 Built in Turkey – Ready for the World

Every door is fabricated at our facility in Turkey using international-grade raw materials, European-quality control systems, and the experience of 30+ years in cold room manufacturing.

- CE-certified, HACCP-compliant, ISO-aligned. • Shipped ready for plug-and-play assembly. • Real documentation, installation drawings, and support — included.

Whether you need one hinged door for a small deli or 100 sliding panels for a logistics hub, we deliver.

❓ FAQs – Cold Room Doors

Do the doors come pre-hung or flat-packed?

Most are shipped pre-hung with frames and gaskets fitted. For large projects, we can also ship flat-packed to reduce freight volume.

What’s the installation time for a standard hinged door?

Usually less than two hours for trained installers. Sliding systems may take longer due to track alignment.

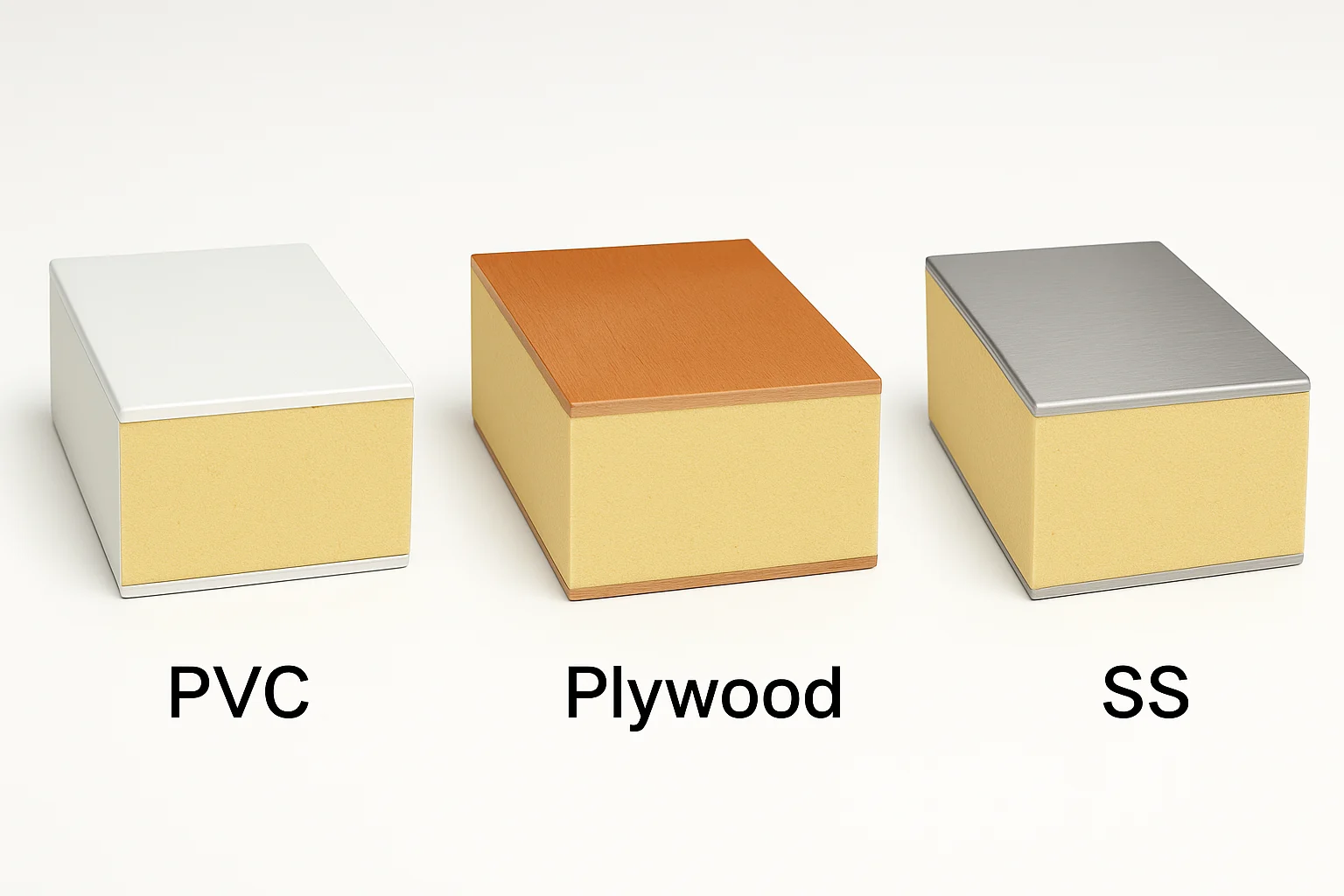

Can your doors be color-customized?

Yes. While stainless and PVC white are common, we also supply RAL-colored finishes when projects demand branding or visibility.

Are spare parts (hinges, rails, gaskets) easy to source later?

Absolutely. All consumables are stocked in Turkey and shipped within days. We also share universal part codes for local sourcing if needed.

How do you prevent condensation around door frames in humid zones?

We integrate anti-condensation heaters in freezer doors and recommend optional strip curtains or air curtains for high-humidity sites like coastal Africa or the Gulf.

💬 Real Projects & Client Testimonials – What Our Partners Say