- Home

- Exhaust & Make-Up Air Units – Engineered Ventilation, Built in Turkey

Extraction Hoods Made in Turkey

Exhaust & Make-Up Air Units – Engineered Ventilation, Built in Turkey

Fixing What the Hood Can’t Do Alone

We’ve seen this again and again in hotel kitchens, fast-food joints, and even hospital cafeterias: hoods are strong, but the air just feels wrong. Either the heat is trapped, the smoke lingers, or the kitchen doors slam from air pressure imbalance. Not cool.

In our turnkey kitchen projects, we don’t just throw in some ducts. We deliver engineered exhaust & make-up air units, all designed and manufactured in Turkey, with the right specs for your cooking type, volume, and local standards. Consultants, procurement teams, and kitchen designers? They love working with us. Because we speak their language.

Let’s explore why this setup matters.👇

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

What’s Included in a Proper System?

A complete system = balanced performance. Without the full picture, you’re only halfway ventilated.

- Exhaust Air Units

- Pull out hot, greasy air from cooking zones

- Roof or wall-mounted systems

- Low-noise motor (<70dB) – your staff will thank you

- Motor housing with thermal + vibration insulation

- Make-Up Air Units

- Push in fresh, filtered, tempered air

- Particle filters as standard

- Adjustable air volume flow

- Electric or water coil heating? Your choice

- Air Volume Balancing Dampers

- Manual or motorized

- Equalizes pressure between exhaust/supply

- Stops backdraft and pressure shocks

- Weatherproof Casing

- Powder-coated steel or galvanized shell

- Built for exterior mounting: roof or wall

Key Functions – What Do These Units Actually Do?

They’re not just fans. They are kitchen safety and comfort managers:

- 🌡️ Control Climate – no more steamy, overheated kitchens

- 💨 Extract Smoke, Odors, Grease – clean air, clean walls

- 🔁 Recover Heat – optional but brilliant for saving energy

- 🔇 Quiet Operation – thanks to smart motor placement and lining

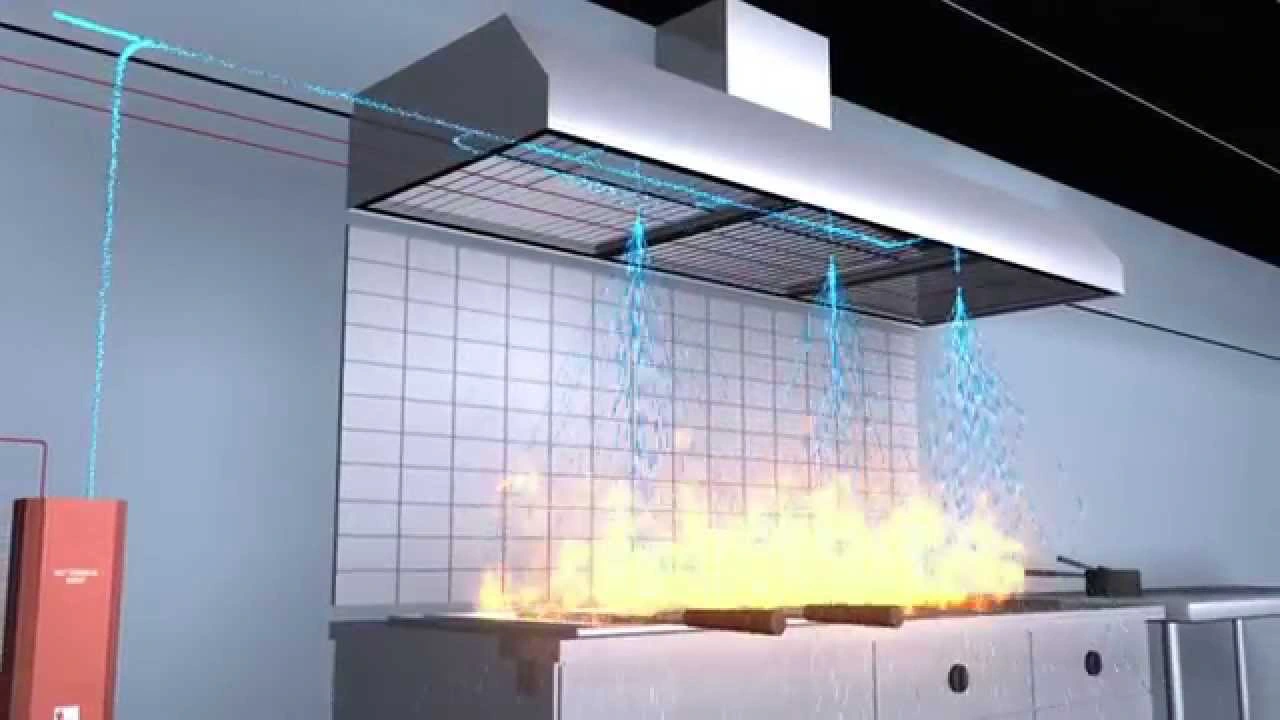

- 🔥 Fire Safety Integration – syncs with suppression systems

Real Kitchen Problems – What Happens Without This?

- Doors slam randomly (yep, that’s negative pressure)

- Chef’s apron flaps mid-shift (airflow turbulence)

- Foggy windows and tired staff (zero fresh air)

👨🍳 True story: One Italian à la carte kitchen in Frankfurt switched to our solution. The chef told us: “We didn’t realize we were working in fog until it cleared.”

Sizing & Capacity – Get It Wrong, and You’ll Regret It

Over-sized? Waste of money and way too loud. Under-sized? Your hoods won’t work, fire risk spikes.

Our sizing considers:

- Total kitchen m² and ceiling height

- Cooking type: grilling, frying, steaming?

- Hood extraction rates (CFM or m³/h)

📐 We run proper calculations with you. It’s part of our service.

💨 Air Flow Engineering – Working with MEP Teams

Larger kitchens come with larger problems:

- Heat pockets near cooklines

- Hood vs. HVAC suction fights

- Smoke escaping into dining areas

So, we coordinate airflow specs with MEP consultants:

- Hood and duct placement

- Make-up air direction (NEVER toward cooktops)

- Return duct design for pressure balance

💬 Chef testimonial: “AC finally worked once the exhaust balance was fixed.”

📉 Energy Efficiency – Designed to Save Money

Our Turkish-made units feature:

- EC (electronically commutated) motors

- Smart controller boxes

- Long-lifecycle fan systems

💡 Heat recovery modules available. Save energy, reduce bills.

🌍 Why Choose Us – Engineered in Turkey, Trusted Worldwide

We’re not a parts dealer—we’re project partners.

- Manufactured in Istanbul, Turkey

- Exported to over 42 countries

- NFPA 96 & EN 16282 compliant

- Certified with CE, ISO, and fire-rating docs

Used in:

- 🏨 Hotels & resorts

- 🏥 Hospitals

- 🍔 QSRs & fine dining

- 🍽️ Education, airports, malls

We make kitchens breathable. Period.

📦 Installation & Utility Requirements

- Voltage: 220–400V / 50Hz

- Mounting: ceiling, roof, or wall

- Add-ons: silencers, dampers, access hatches

- External weather insulation mandatory for rooftop units

🧰 Important: Measure pressure loss across ductwork to avoid overloading your fan.

🧼 Maintenance Tips & Smart Add-Ons

- Clean or replace filters every 2–3 weeks

- Belt tension & motor inspection monthly

- Swap carbon filters when odor builds

- Consider anti-vibration feet, weather hoods, pressure gauges

📊 Exhaust vs. Make-Up Air Units – Core Differences

Feature | Exhaust Unit | Make-Up Air Unit |

Function | Remove hot/greasy air | Bring fresh, filtered air |

Placement | Roof / Exterior Wall | Roof / Ceiling Plenum |

Flow Direction | Outward | Inward |

Heat Recovery | Optional | Frequently Included |

Fan Type | Axial or Centrifugal | Centrifugal Preferred |

❓ FAQ – Exhaust & Make-Up Air Units

Is make-up air really needed in small kitchens?

Yes. Even compact kitchens need balanced airflow to stop doors slamming, smoke drifting, and pressure issues.

Can these systems be added to existing kitchens?

Definitely. Modular wall-mounted or rooftop models can retrofit into most projects without heavy redesign.

How do you stop freezing cold air in winter?

By adding coil heating – either electric or hot water – so incoming air stays tempered and comfortable.

Are silencers worth installing?

Yes. Acoustic packages reduce motor and airflow noise, especially in FOH or hospital kitchens.

Do these units integrate with fire suppression?

Absolutely. Units can connect to BMS/fire panels and auto shut down airflow when suppression triggers.

Real Projects & Client Testimonials – What Our Partners Say