- Home

- Walk-In Cold Rooms for Fruit & Vegetable Storage

Walk-In Chiller Rooms & Freezers Made in Turkey

Walk-In Cold Rooms for Fruit & Vegetable Storage

Ever opened a crate of lettuce and found soggy leaves? Or bit into a mango that’s gone soft before its time? Yeah, we’ve seen it too — freshness can vanish faster than you think. A little too much heat, a drafty corner, or a few hours with the wrong humidity — and your quality slips before you know it.

That’s why we don’t just build cold rooms — we build fresh-keeping environments tailored to fruits and vegetables. At our facility in Turkey, we design systems that balance air, temperature, and humidity to help your produce stay crisp, colorful, and full of value. Whether you’re slicing cucumbers in a resort kitchen or packing crates of citrus for export, we help you protect every box.

From roadside vendors in Zanzibar to citrus hubs in Cameroon, our walk-in cold rooms are helping businesses take control of freshness, reduce waste, and deliver better produce — every single day.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

🍎 Why Your Produce Needs the Right Cold Storage

Fresh produce doesn’t wait. And it doesn’t forgive. If you’ve ever had to throw out a box of soft tomatoes or watched your spinach droop before lunch service, you know this isn’t just about storage — it’s about doing the job right.

That’s why we don’t believe in “one size fits all.” Every fruit and vegetable has its own tempo. We design walk-in chillers that meet your products where they are — fragile, breathing, and full of life:

- 🌡️ Climate Control That Knows What You’re Growing: Every system is tuned for your crop — because root vegetables, berries, and herbs all ask for different things.

· 💧 Humidity Like It’s Meant to Be: Not too dry, not too wet — just enough to keep lettuce crisp and mangoes juicy.

· 💨 Airflow That Cares: Gentle, steady circulation that cools without bruising or drying out your inventory.

· 🧽 Surfaces That Don’t Push Back: Sealed, smooth interiors you can wipe down fast, so cleanup never eats into your day.

· 📦 A Layout That Moves Like You Do: Whether it’s pallets, crates, or bins, we’ll design around how your team works — not the other way around.

🌍 Who We Work With in the Fresh Produce Chain

We team up with people who handle fast-moving produce, day in and day out:

. 🍊 Citrus exporters in Egypt

· 🥬 Salad prep kitchens in coastal resorts

· 🛒 Grocery chains and wholesalers in warm regions

· 🧺 Packing co-ops and small-scale farmers

· 🏷️ Fresh market vendors in tropical climates

· 🥑 Avocado & Banana ripeners

🧱 Cold Room Panels – Designed to Keep Freshness In

Feature | Description |

🔲 Type | Modular / Sandwich – customized for produce handling |

🧊 Insulation | PUR foam, 40–44 kg/m³ |

📏 Thickness | 100 mm (chillers), 120 mm (freezers) |

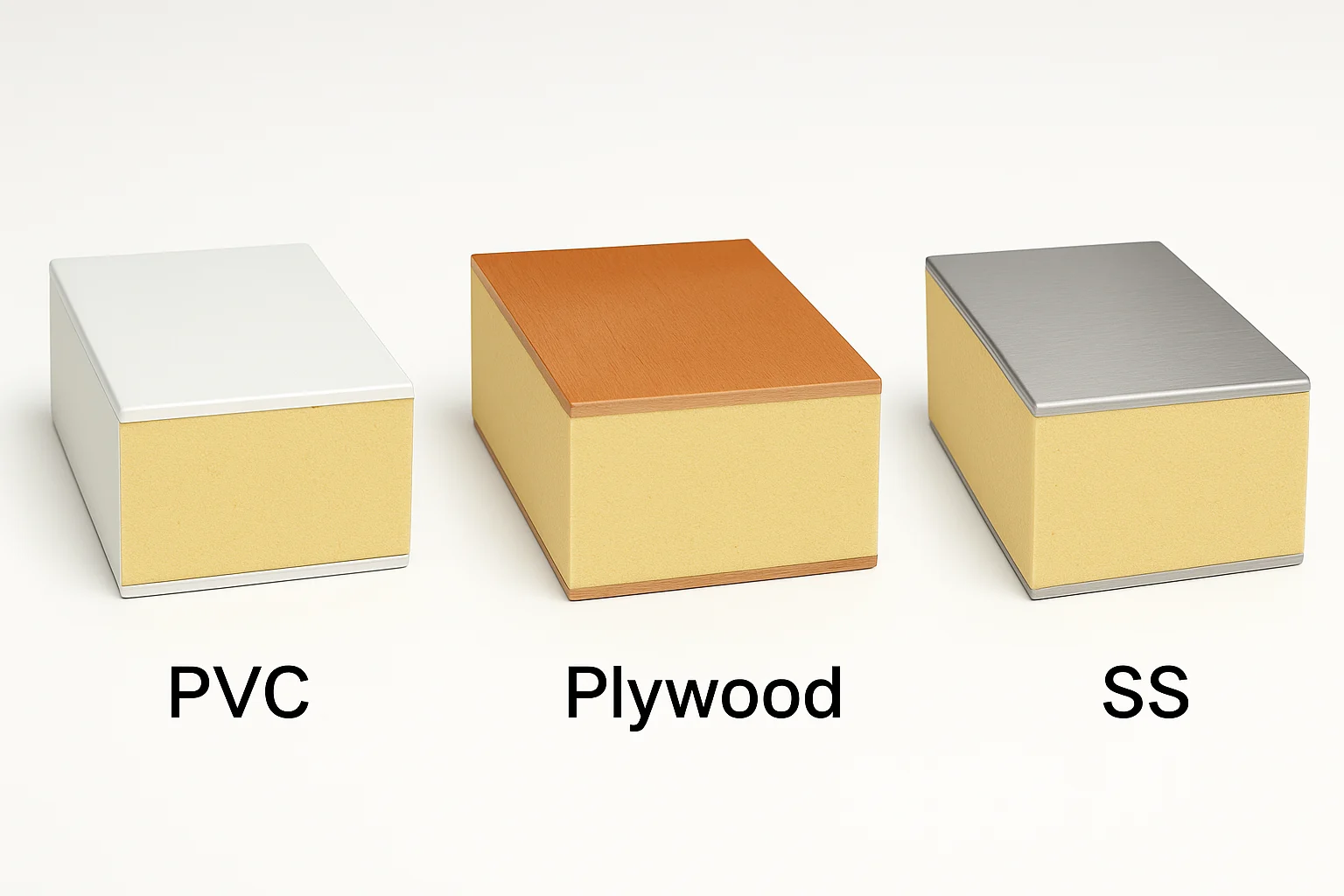

🧽 Surface Finish | Smooth PVC or stainless steel – antibacterial, easy-clean |

🚫 Floor Panels | Anti-slip, waterproof, washable – ideal for crate zones |

🔗 Panel Joint | Cam-lock tongue & groove – leak resistant |

🧼 Corners | Rounded and seamless for fast sanitation |

🪵 Floor Panel Options for Produce Storage

. 🧲 Checker Aluminum – Durable and easy-clean for pallet zones

· 🧼 PVC Non-Slip – Grippy, easy to hose down

· 🍃 Stainless Steel (304) – Ideal where washdowns are frequent

🔄 Flexible Installation Approaches

. 🚧 Ramp entry for crate trolleys

· 🕳️ Recessed layouts for market or prep rooms

· 🧱 Floor-slab mounted for modular pack houses

· ❄️ Foam underlayers when full panel floors are not used

🧱 Walls & Ceilings That Don’t Trap Moisture

. 🧱 Wall Panels: Smooth, washable, and food-safe

· 🔼 Ceiling Panels: Sag-proof, insulated against condensation

🚪 Door Systems that Work Under Pressure

. 🚪 Hinged – For standard access with tight sealing

· 🚪 Swing & Flip-Flap – Hands-free or push-through entry

· 🚪 Sliding – For wider batch or rail system access

💡 Lighting, Sensors & Accessories

- 💡 LED lights – High visibility, water-sealed

· 🌡️ Smart digital monitors – Temperature + humidity control + alerts

· 🚪 Air curtains & strip curtains – Keep cold in, heat out

· 🔩 Shelving, crates, ramps, and produce-safe liners

🚪 Cold Room Doors for Produce Environments

. 🚪 Hinged Doors – With tight seals and smooth access

· 🚪 Sliding – For larger bin or bulk entry

· 🚪 Flip-Flap – For fast kitchen or market access

📦 What Sets Our Produce Cold Rooms Apart

. 🇹🇷 Built in Turkey – CE certified, export-ready, HACCP compliant

· 🌿 Designed for fruits & veggies – not retrofitted general units

· 💧 Humidity and airflow management for delicate produce

· 🔁 Modular systems that evolve with your capacity

· 📞 Expert support and guided delivery, worldwide

❓ FAQ – Fruit & Vegetable Cold Rooms

What is the ideal storage temperature for fruits and vegetables?

Most vegetables keep best between +2°C and +5°C, while fruits often need slightly higher ranges depending on type. Bananas, for example, should not be stored below +12°C to avoid chilling injury.

Why is humidity control so important for produce cold rooms?

If humidity is too low, lettuce wilts and herbs dry out. If it’s too high, mold and decay accelerate. Balanced humidity helps keep freshness and reduces waste.

Can one cold room store all fruits and vegetables together?

Not always. Some fruits like bananas release ethylene gas, which speeds up ripening of nearby produce. Separate zones or dual-chamber systems prevent cross-contamination.

How do consultants plan BOQ integration for produce cold rooms?

They specify humidity control units, drainage, shelving layouts, and airflow zoning. Clear BOQ entries ensure the system matches operational needs from day one.

What ROI can farmers and distributors expect from Turkey-built produce cold rooms?

Most co-ops and wholesalers report spoilage reduction of 30–40%, paying back investment in under 2 years. For exporters, extended shelf life means fewer rejected shipments.

💬 Real Projects & Client Testimonials – What Our Partners Say