- Home

- Hot Kitchen Cold Rooms for Hospitality & F&B Projects

Walk-In Chiller Rooms & Freezers Made in Turkey

Hot Kitchen Cold Rooms for Hospitality & F&B Projects

You’ve been there — the grills are blazing, steam is rising, and the cold room door never stays shut for long. That’s why standard cold rooms just don’t cut it.

That’s why we build every hot kitchen cold room specifically at our Turkish factory — with the demands of high-heat environments in mind.

After delivering over 100 custom systems worldwide, we’ve learned exactly what hot kitchen environments demand — both for safety and efficiency, even when temperatures outside the cold room are pushing 40°C or more.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

🔧 Built for High Heat

What Makes Our Hot Kitchen Walk-in Chiller Rooms Different These systems are installed just next to the cooking line or cooking island areas where heat is at its highest. That’s why every component we use, from insulation to door seals, is designed to withstand harsh and extreme conditions:

- 🔲 High-density PUR insulation (40–44 kg/m³) – reinforced against heat

· 🧼 Hygienic interior surfaces coated with stainless steel or food-contact PVC

· 🚫 Non-slip safety floor coverings for busy kitchen staff

· ❄️ Rapid cooling systems suitable for frequently opened and closed doors

· 📏 Compact layouts for narrow spaces

👨🍳 Who It’s For Our hot kitchen cold rooms are safely used by professionals such as:

🍽️ Hotel, resort and restaurant chefs and kitchen managers

· 🧱 Architects and kitchen consultants working on food and beverage projects

· 🏥 Hospital kitchen planners and catering contractors

· 🚚 Cold room distributors and general contractors involved in tourism investments

From the Maldives to Ghana, we’ve helped many customers keep their supplies fresh and safe — right next to the hot kitchen line.

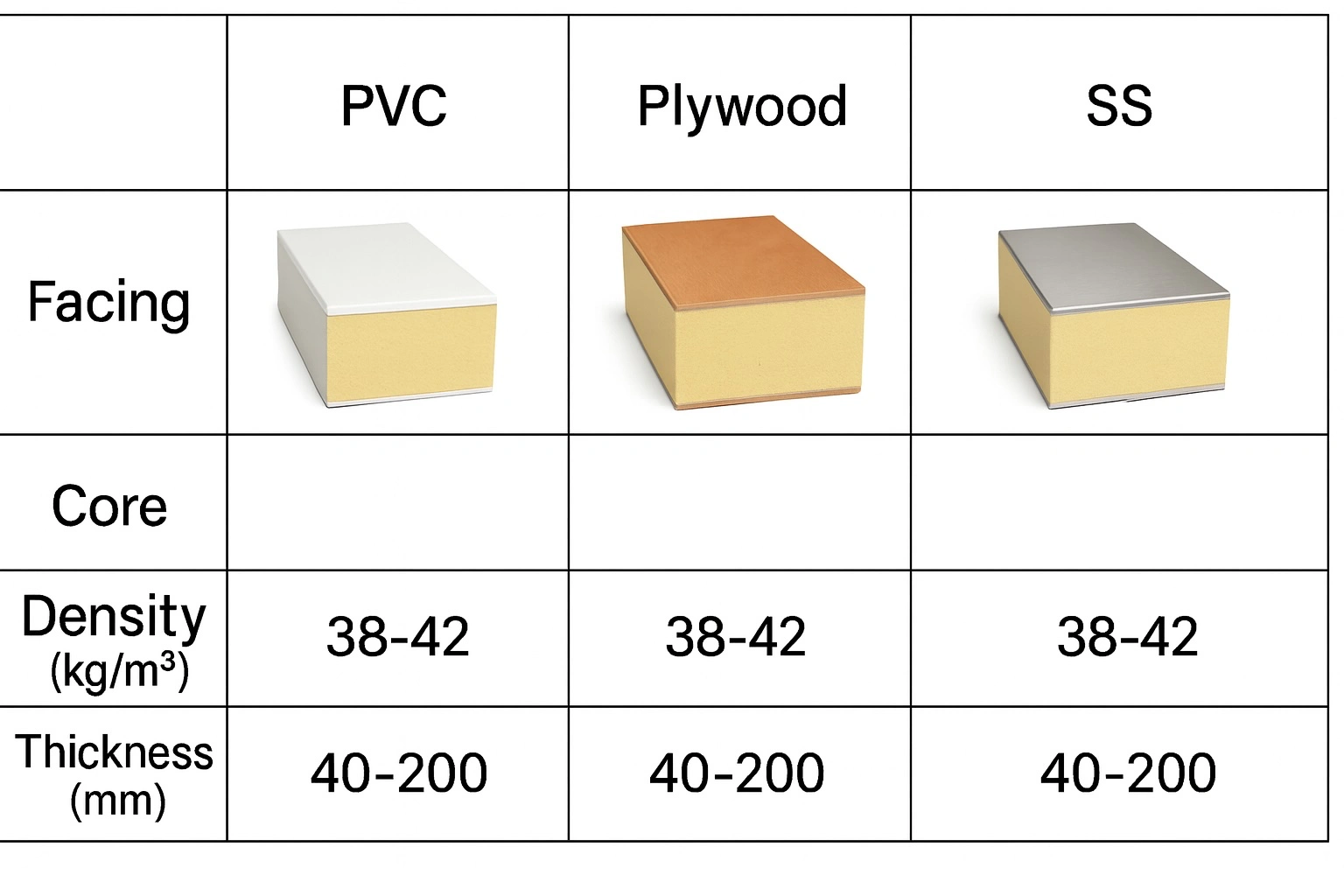

🧱 Cold Room Panels – Insulated, Tongue-and-Groove Construction Designed to fit right into narrow, heat-intense kitchens, our cold room panels come pre-fabricated from our Istanbul facility and connect easily on site. With a high-density polyurethane core and food-grade interior skins, they’re built to hold the cold when everything around them is hot.

Feature | Description |

🔲 Type | Sandwich / modular construction |

🧊 Insulation | PUR foam, 40–44 kg/m³ |

🌡️ Thermal Conductivity | ~0.20 W/m·K |

📏 Thickness | 80–100 mm (chillers), 100–120 mm (freezers) |

🧽 Finishes | Stainless (AISI 304/316), PVC, galvanized, or aluminum |

🚫 Floors | Plywood, stainless, PVC, or checker aluminum |

🔗 Joint | Cam-lock tongue & groove |

🧼 Corners | Rounded, antibacterial, easy to clean |

🪵 Floor Panel Applications – Built for Hygiene and Durability In fast-paced kitchens, the floor takes constant foot traffic, spills, and heavy loads. That’s why our floor panels are reinforced and coated for long-term, hygienic use:

- 🟫Plywood Core Panels– Strong and stable, suited for light to medium-duty commercial use.

· 🧼 Non-Slip PVC Coating – Prevents slips and supports safe food handling.

· 🧲 Checker Plate Aluminum – For rugged conditions, cleaning ease and corrosion resistance.

· 🥩 Stainless Steel (AISI 304/316) – Ideal for meat, seafood, and open flame proximity.

🔄 Alternative Cold Room Floor Solutions

Not every kitchen layout needs a standard floor. We offer:

- 🚧Flush-Mounted Ramp Floor Panels– When accessibility and mobility are key.

· 🕳️ Recessed Floor Installation (Pit Mounting) – To create a fully embedded cold room footprint.

· 🧱 No-Panel Concrete Base – When built directly onto insulated slab floors.

· ❄️ Foam or Insulation Layer Under Concrete – For non-panel kitchens needing insulation beneath concrete.

🧱 Wall & Ceiling Panel Structure – Holding the Cold, Sealing the Hygiene Even in hot and humid back-of-house areas, our panels maintain their structure and seal.

- 🧱Wall Panels– Impact- and moisture-resistant with food-safe coatings and smooth finishes.

· 🔼 Ceiling Panels – Designed for stability, sag prevention, and corrosion protection.

🚪 Cold Room Door Types – Hinged, Sliding, Monorail, Flip-Flap Hot kitchens require fast, durable access points. We deliver:

- 🚪 Hinged Cold Room Doors – Simple and secure, ideal for compact kitchens.

· 🚪 Flip-Flap Doors – Swing-open style for fast entry without compromising temperature.

💡 Lighting, Controls & Curtain Accessories Proper visibility, temperature control and airflow separation are critical:

💡 LED lighting – Condensation-resistant, long-lasting, and safe.

· 🌡️ Digital Monitoring – Includes remote alarms, HACCP compliance, and USB logging.

· 🚪 PVC Curtains & Air Curtains – Efficient cold-air retention solutions.

· 🔩 General Accessories – Ramps, shelving, bumpers and more.

🏷️ Made in Turkey. Ready for the World.

All systems are manufactured in Turkey and shipped to projects worldwide, with components carefully packaged and detailed installation instructions:

- 📄 Fully compliant production with CE and HACCP certification

· 🔧 Turnkey service from design to installation

· ❄️ Cooling systems resistant to 43°C tropicalised ambient temperature (Bitzer, Daikin, Tecumseh)

· 🚪 Hinged or flip-flap fast access doors

· 🌐 Professional export support with our experienced logistics team

❓ FAQ – Hot Kitchen Cold Rooms

Why do cold rooms near hot kitchens fail more often?

Standard cold rooms aren’t insulated for constant external heat, steam, and door openings. In these environments, seals degrade faster and compressors overwork, leading to breakdowns.

What insulation thickness is best for hot kitchen walk-in chillers?

Most chefs prefer 100 mm PUR panels. The higher density (40–44 kg/m³) ensures stable cooling when the outside air can hit 40°C or higher.

Can I install a cold room directly beside the cooking line?

Yes — but only if panels are reinforced and cooling units are tropicalized. Otherwise, temperature fluctuations can cause food safety risks.

How should hot kitchen cold rooms be integrated into MEP layouts?

They must be shown with higher ventilation clearance, drain points, and electrical loads adjusted for frequent compressor cycling. Coordination with consultants avoids redesign later.

What ROI can hotels expect when using Turkey-built hot kitchen cold rooms?

Energy savings and fewer breakdowns often cut maintenance budgets by 20–25%. Resorts in the Maldives reported full ROI in less than 3 years thanks to durability under humid heat.

💬 Real Projects & Client Testimonials – What Our Partners Say