- Home

- Cold Room Panels – Insulated, Tongue-and-Groove Construction

Walk-In Chiller Rooms & Freezers Made in Turkey

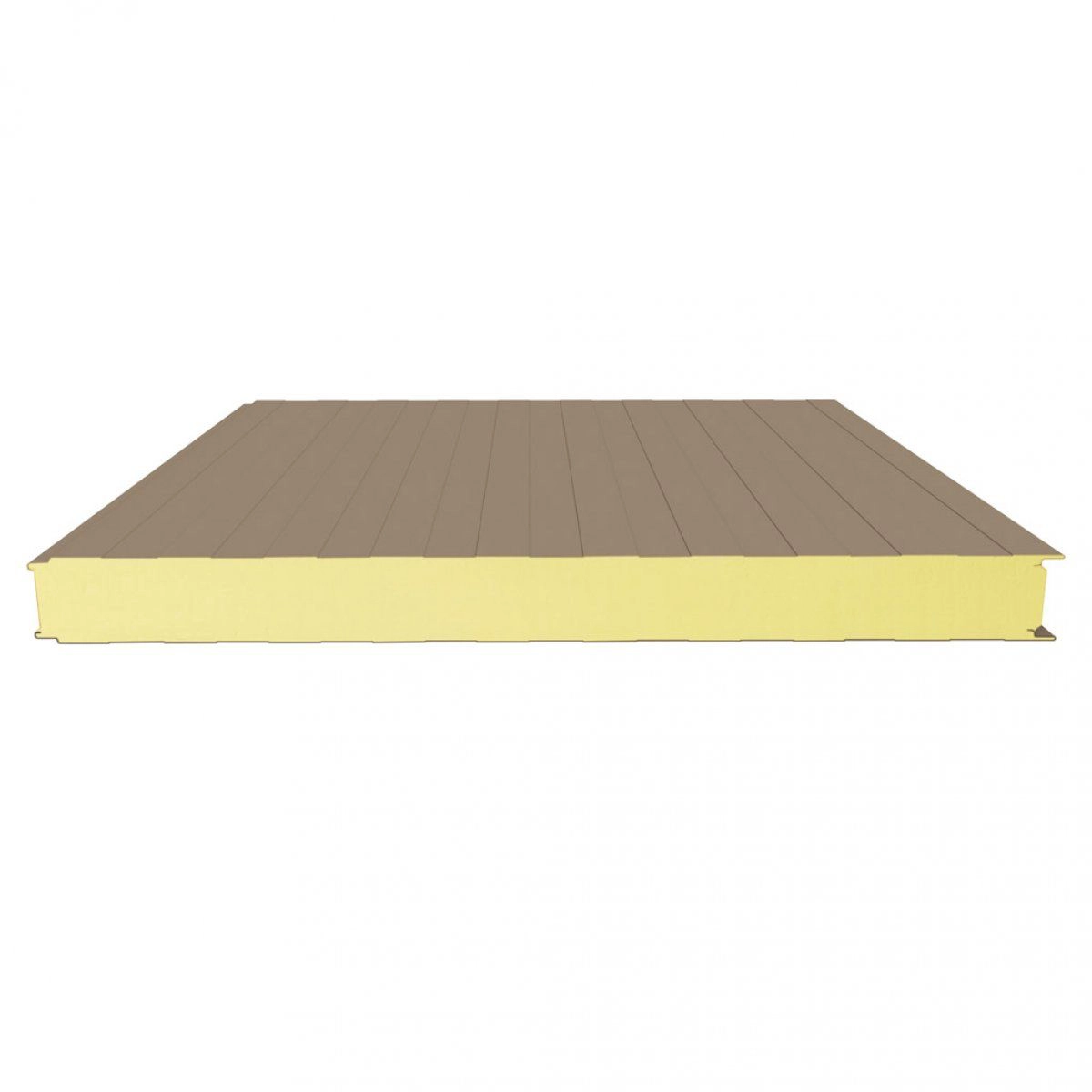

Cold Room Panels – Insulated, Tongue-and-Groove Construction

You might not think about the panels much. Most people don’t. But when your walk-in cold room is running 24/7, keeping thousands of dollars in food, medicine, or produce safe, it’s the panels that take the hit. Heat, moisture, time, pressure. Day in, day out. If they fail? Everything else does too.

That’s why we build ours with purpose.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

🌟 Made in Turkey, Built for the World

Each panel comes straight from our facility in Turkey, designed with high-pressure-injected polyurethane (PUR) foam at 40–44 kg/m³. That means dense, dependable insulation that actually staysinsulated. Tongue-and-groove edges with cam-lock fasteners make assembly so smooth, most installers just smile. No headaches. No surprises.

Panel Features That Actually Matter:

- 🔹 Tongue-and-Groove Cam-Lock System — These aren’t your average panels. They click, seal, and staysealed. Even after years of slamming doors and peak loads.

- 📏 Panel Thickness — Choose from 80 mm for chillers or 100/120/150 mm for freezer-grade needs. Thicker = colder = better.

- 🪑 Food-Safe Finishes — Stainless steel (AISI 304/316), galvanized sheet, antibacterial PVC, or food-grade aluminum. Smooth, easy-clean surfaces = fast sanitation.

- 🚮 Zero Bacteria Zones — Rounded corners and smart junctions. No weird edges where grime can settle.

- ❄️ Thermal Conductivity — ~0.20 W/m·K. Keeps your energy bills from climbing and your temps from swinging.

“One of our clients in Nairobi replaced imported panels with ours – cut energy waste by 17% and the install finished two days early.”

🌬️ Built for Any Weather, Any Industry

Tropical heat? Salty coast? High-altitude bakery? These panels have already seen it all. We’ve built cold rooms in desert warehouses, on island resorts, and in mountainside hospitals. Because temperature control shouldn’t depend on your zip code.

🚪 Floor & Ceiling Panels

Yes, we cover it all – including above and below:

- 🛍️ Flooring Options: Plywood + checker plate, stainless steel for hygiene zones, or aluminum tread for heavy-load areas.

- 🌅 Ceiling Strength: Suspended lighting, ceiling-mounted evaporators, insulation consistent across the top – no weak spots.

“A seafood exporter in Sri Lanka told us our ceiling panel held strong after a storm nearly flooded his loading bay. Not a single leak.”

📊 Efficiency That Pays Off

Our panels don’t just trap cold — they earn their keep:

- Less compressor runtime

- Faster pull-down temps

- Lower energy bills

- Extended shelf life for perishables

🧱 For First-Time Buyers: What to Know

If you’re building your first cold room, here’s the big stuff in plain words:

- Thicker panels = better for hot places or freezer use

- Cam-locks = easier installs and fewer gaps

- Food-grade finishes = faster inspections

Don’t get sold on fancy extras unless your space truly needs them. We’ll help you plan what matters.

❓ FAQs – Cold Room Panels Edition

How do I decide panel thickness for my project?

For chillers in mild climates, 80–100 mm works. Freezer rooms or tropical zones need 120–150 mm to keep temperatures steady and energy use down.

Do panels come pre-cut or custom-sized?

Both options exist. Standard lengths fit most builds, but we also cut panels to match your BOQ and layout drawings, reducing waste on-site.

What about after-sales support if a panel gets damaged during install?

We record every shipment by code. If one panel is damaged, we can ship a replacement with identical specs — even years later.

Are food inspectors okay with PVC finishes?

Yes. Antibacterial PVC is HACCP- and CE-compliant. Many clients mix PVC for walls and stainless for floors to balance hygiene and budget.

Can panels be re-used if I relocate my cold room?

Definitely. The cam-lock tongue-and-groove design allows disassembly and re-installation without losing insulation quality.

💬 Real Projects & Client Testimonials – What Our Partners Say