- Home

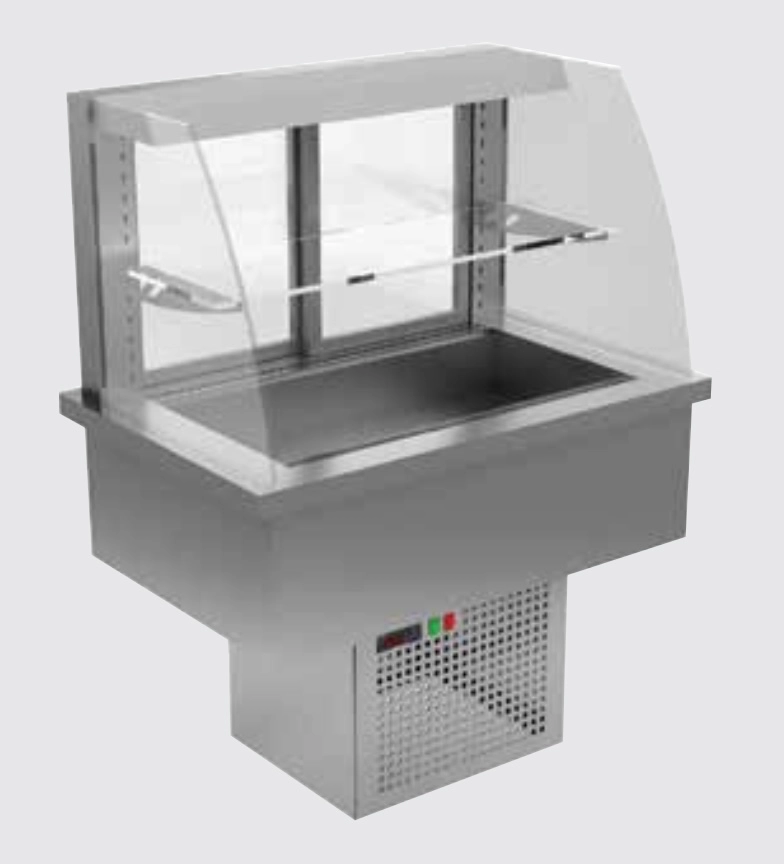

- Drop-In & Built-In Food Display Cabinets – Hot, Cold & Ambient

Food Display Cabinets Made in Turkey

Drop-In & Built-In Food Display Cabinets – Hot, Cold & Ambient

The Project-Ready Choice for Modern Kitchens

If you ever plan a new kitchen or refurbish your food line, you know – drop-in and built-in food display cabinets are game changer. Consultants, architects, even BOH and FOH operators say these units don’t just look clean, but make service faster, easier, and more professional. Made in Turkey with custom options for project teams, these displays can be integrated into buffet counters, open kitchens, staff canteens, or even fast-casual restaurant lines.

What makes them special? You can choose hot, cold, or ambient modules and combine all in one counter—so your design looks continuous and your service flows smooth. Contractors like the flexibility, designers love the clean lines, and operators say it’s much easier to keep things hygienic.

Key Advantages for Drop-In/Built-In Food Display Cabinets

- Hygienic integration: No food falling behind the unit, easy to wipe around—health inspectors prefer this style.

- Smooth & stylish: Matches countertop materials, blends into any concept—bar, café, hotel, supermarket.

- Custom size & GN compatibility: Pick GN1/1, GN2/1, EN trays or full custom, just what your chef or consultant wants.

- Fast installation: Fits directly into new or existing counters; project contractors save days of work.

- Flexible: Combine hot, cold, ambient in a single line, perfect for breakfast buffets or multi-concept venues.

- Hidden wiring & drainage: Clean look, safer workspace, less maintenance for operator and kitchen team.

- Front-of-house & back-of-house: Equally useful in guest zones or kitchen prep area; FOH looks modern, BOH works smooth.

Design & Integration – Project Customization

Every project is different. Some want a full hotel buffet island, others just a compact salad bar or a pastry drop-in for a bakery. Turkish manufacturers export cabinets made for all these project types:

- Hotels & Resorts: Big breakfast counters, show kitchen pass lines, modular serving.

- Restaurants & Cafés: Salad bar, pasta bar, hot/cold food lines, cake stations.

- Bakeries & Deli Shops: Cold sandwich line, ambient bread drop-in, chocolate display.

- Canteens, Hospitals & Institutions: Hot meal line, soup bar, salad or dessert cooling.

- Corporate & Staff Restaurants: Multi-zone counters, high capacity, quick serve.

Designers, architects, and consultants can specify any finish—stainless steel, granite, composite, color panel, glass top—so the display becomes invisible or a showpiece. Lighting, branding, controls, and even remote cooling units are all available for big projects.

Technical Features Table (Drop-In/Built-In Models)

Feature | Hot Drop-In | Cold Drop-In | Ambient Drop-In |

Temp Range | +30 – +90°C | 0 – +8°C | Room Temp (18–25°C) |

GN Compatibility | GN1/1, GN2/1, Custom | GN1/1, GN2/1, Custom | GN1/1, GN2/1, Custom |

Control Type | Digital/Manual | Digital/Manual | None/Manual |

Drainage | Yes (Steam) | Yes (Condensate) | Not Required |

Lighting | LED Standard | LED Standard | LED Optional |

Power | 230V / 50Hz | 230V / 50Hz | None |

Finish Options | SS, Granite, Custom | SS, Granite, Custom | SS, Granite, Custom |

For full technical docs or project specs for your consultant, just ask—our team helps with every detail, fast.

Certificates, Warranty & Export Support

All drop-in/built-in models are manufactured in Turkey and exported worldwide with CE, HACCP, and ISO certificates. 1-year standard manufacturer warranty for every export, plus project consultancy and service/spare part network for long-term support.

How to Select the Right Drop-In/Built-In Display for Your Project?

- What’s your menu? Hot, cold, ambient, or a mix? Decide what you’ll serve most, then match the right modules.

- How many guests? Busy hotel, school, or café—each needs different size/volume.

- Where will it be? FOH (for guest self-service and display) or BOH (staff only, speed, hygiene)?

- Counter design: Show your plans to your consultant—choose a finish and layout that fits your project style.

- Utilities: Check space for drainage, power, cleaning—share details early, saves time.

FAQ

Can I combine hot, cold, and ambient modules in one counter?

Yes. That’s the main benefit of drop-in systems. You can seamlessly mix hot, cold, and neutral units under one continuous counter design.

Are these cabinets hard to install or require special tools?

Not at all. Most models are plug-and-play. They drop into pre-cut counters and connect to power and drainage — no complex tools or delays.

Can I match the cabinet finish to my counter or interior design?

Absolutely. Options include stainless steel, granite, glass, or custom color panels. We also offer branding and lighting integration.

Are these cabinets suitable for both FOH and BOH use?

Yes. They’re designed for visibility in guest zones (FOH) and efficiency in kitchen areas (BOH). Hygiene, access, and cleanability are optimized for both.

What maintenance is required for these drop-in units?

Daily cleaning is simple—just wipe surfaces. No hidden corners. Condensate and steam trays are removable. Digital controls ensure safe operation.

What Operators Say & Get Your Pizza Kitchen Project Quote✨

Food Display Cabinets