- Home

- Semi-Hermetic Split-Type Cooling Units

Walk-In Chiller Rooms & Freezers Made in Turkey

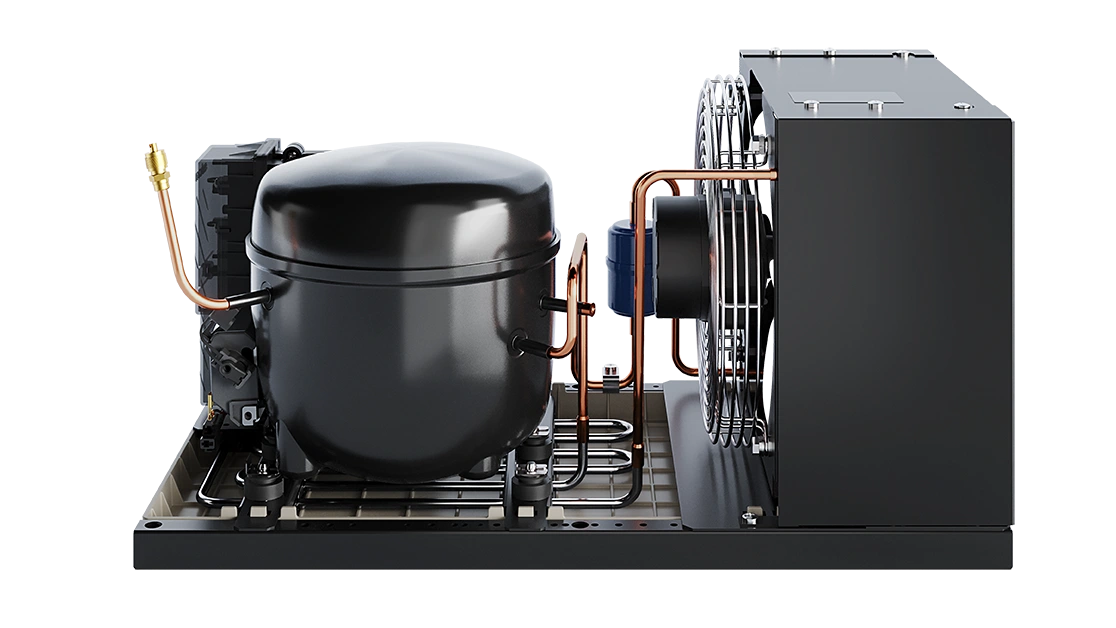

Semi-Hermetic Split-Type Cooling Units

Some cooling jobs are easy. This isn’t one of them.

When your cold room feeds hundreds, stores tons, or gets opened every 3 minutes — you don’t want “almost enough” cooling. You want muscle. Control. And something that doesn’t flinch when the pressure’s on.

That’s what semi-hermetic systems are made for. Built right here in Turkey, these units were made to show up, shut up, and cool hard — even when the sun’s melting the sidewalk outside. From desert warehouses in Oman to meat packing plants in Lagos, these machines hold their chill without making a fuss.

1-Year Factory Warranty

Service in 90+ countries

Spare parts in Turkey, UAE

💪 Why Semi-Hermetic Just Hits Different

- 🔧 Easy to Open, Easy to Fix:Unlike sealed units, these are repairable. Your tech can open them up, swap a part, and have it running before lunch.

- 📦 Made for Big Spaces:Got more than 40 cubic meters to cool? No worries. These units love big jobs.

- 📈 Grows with You:Business expanding? Add new cold rooms? This unit’s got bandwidth.

- 🧱 Built Like a Truck:Strong shell, vibration resistance, oversized parts. This thing’s a tank in disguise.

- 📲 Add-Ons That Make Sense:Smart sensors. Digital panels. Remote alarms. All there if you want ‘em.

🌍 Manufactured in Turkey. Working Everywhere.

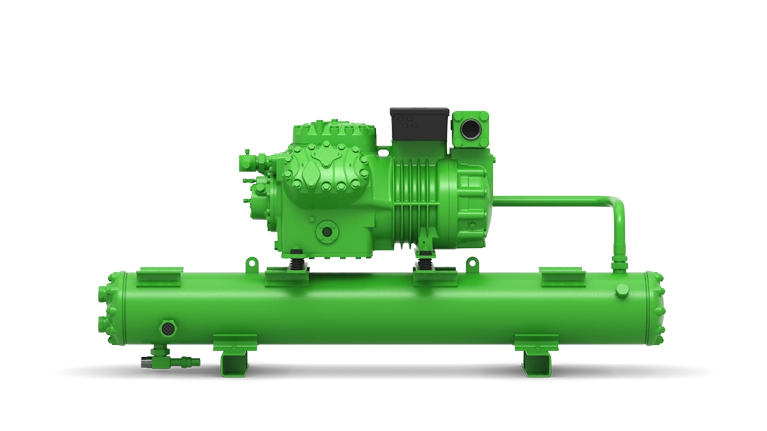

We build these with top-tier compressors — Bitzer, Copeland, Dorin — all tested to handle the roughest environments. Whether you’re in coastal humidity or dry desert heat, these units stay cool.

And yes — CE-certified, HACCP-aligned, exported globally with zero customs drama. Just clean paperwork and solid machines.

🧊 Where These Units Shine

- Walk-in freezers or chillers above 40 m³

• Meat and poultry processing

• Cold logistics depots

• Production kitchens and factories

• Tropical zone cold chains

❓ FAQ – Semi-Hermetic Split-Type Cooling Units

What kind of cold room size really requires a semi-hermetic system?

Anything above 40 m³, or with heavy product turnover, benefits from the extra capacity. They’re especially right for meat depots, poultry storage, and multi-shift kitchens.

How do semi-hermetic units support long-term investment compared to hermetic?

They’re repairable — meaning instead of replacing the whole compressor, you just service it. Over 10 years, that often saves 25–30% in ownership cost.

Can these systems handle unstable power grids in Africa or remote regions?

Yes. Semi-hermetic compressors are robust, with higher tolerance for voltage fluctuation. Many clients pair them with stabilizers for extra insurance.

Are they difficult for local technicians to maintain?

Not at all. Basic oil checks and routine cleaning are enough. When needed, parts are globally available, so downtime is minimal.

Do semi-hermetic units work in extreme climates like the Gulf or coastal West Africa?

Absolutely. With proper installation, they operate reliably in +45°C desert heat or high-humidity coastal environments without performance drops.

💬 Real Projects & Client Testimonials – What Our Partners Say