- Home

- Supporting Equipment & Accessories for Commercial Kitchens

Extraction Hoods Made in Turkey

Supporting Equipment & Accessories for Commercial Kitchens

Why Supporting Equipment Defines Kitchen Safety & Flow

In dozens of turnkey kitchen projects — from hotel resorts in Zanzibar to staff canteens in Berlin — we seen how “invisible” accessories often decide whether a commercial kitchen runs smooth or face downtime. Filters, exhaust systems, and fire suppression units don’t get headlines, but they keep inspectors happy, staff safe, and foodservice operations alive.

As part of our Turkey-made turnkey kitchen projects, we integrate grease filters, exhaust & make-up air units, and fire suppression systems that are built for compliance, engineered for heavy use, and ready for export. Contractors, consultants, and facility managers trust these supporting systems because they solve real problems, not just tick boxes.

Not every sink is for food, not every hood is for looks — but every kitchen needs protection.

Grease Filters & Accessories – First Line of Defense

Grease filters are more than metal mesh. They protect ducts, reduce fire risk, and make hoods last longer. We’ve seen projects in Dubai where missing baffle filters led to oil dripping into prep zones, causing hygiene failures.

Key Features & Options:

- Stainless Steel Baffle Filters – easy to clean, dishwasher-safe

- Honeycomb & Mesh Types – high efficiency for fast-food chains

- Drip Trays & Grease Cups – keeps oil under control

- UV & Electrostatic Options – advanced solutions for smoke-heavy kitchens

- Custom Sizes – for hood retrofits or bespoke duct setups

✅ Why it matters: A single clogged filter can raise hood fire risk by 70%. Our Istanbul factory designs filters that match airflow volumes and MEP drawings for each project.

Exhaust & Make-Up Air Units – Balanced, Breathable Kitchens

If the hood breathes out, the make-up air unit must breathe in. In too many kitchens across Africa and Asia, we’ve seen chefs complain: “The smoke clears, but the air feels heavy.” That’s a sign of poor balancing between exhaust and supply.

Turkey-engineered exhaust & supply systems ensure fresh air, safe pressure levels, and HACCP compliance.

Configurations We Deliver:

- Exhaust Fans – low-noise, high-efficiency motors

- Make-Up Air Units – tempered air supply, balanced with hood extraction

- Ductwork & Diffusers – stainless or coated steel

- Speed Controllers & Sensors – energy saving + staff comfort

- HEPA & Activated Carbon Add-ons – for hospitals or smoke-heavy kitchens

🌍 Real Projects: In Nairobi hospital kitchens, balanced make-up air reduced staff fatigue. In Riyadh 5-star resorts, exhaust systems designed with consultants passed NFPA codes on first inspection.

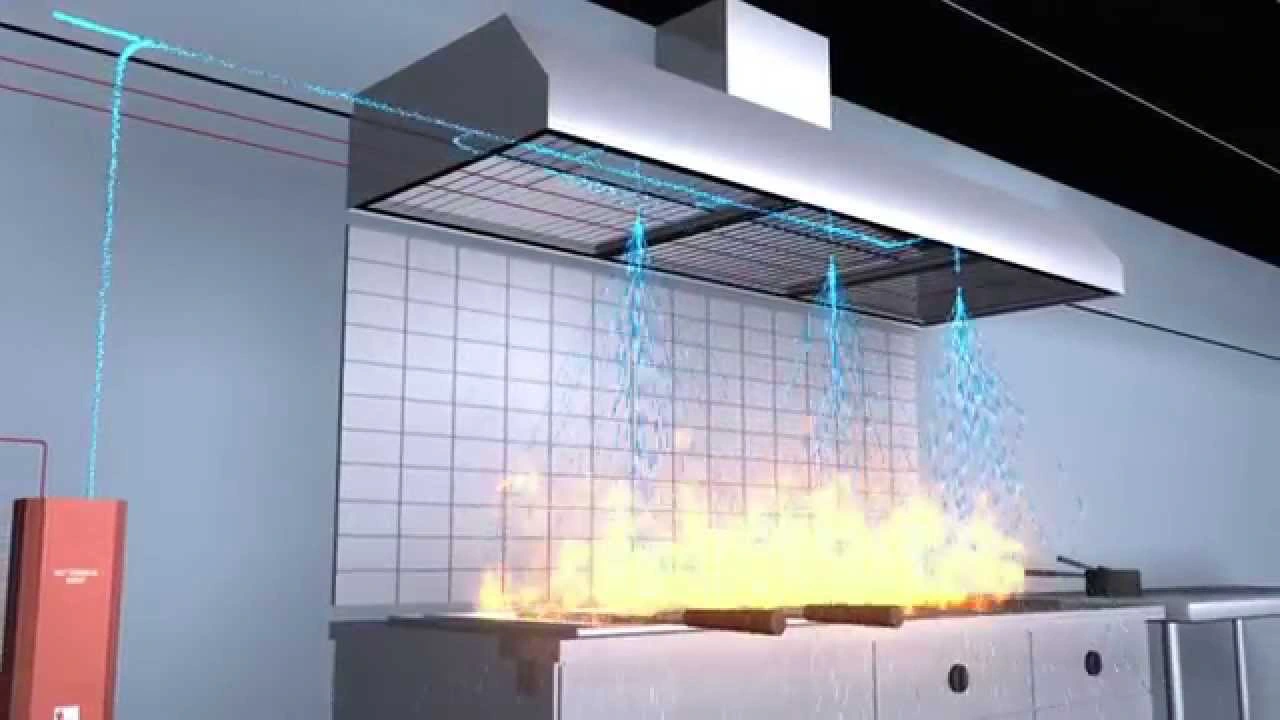

Fire Suppression & Safety Systems – Non-Negotiable Protection

We seen this too often: one spark in a fryer, one unattended grill, and in 30 seconds a kitchen face disaster. That’s why our fire suppression systems built in Turkey are mandatory in our turnkey projects.

System Components:

- Nozzles & Piping – stainless, pressure-rated

- Wet Chemical Cylinders – UL300 certified

- Detection Lines – fusible links melting at 93°C–260°C

- Manual Pull Stations – wall-mounted, staff-ready

- Micro-Switch Relays – shuts off gas/electric instantly

Variants We Offer:

- Ansul R-102 Systems – standard wet chemical, retrofit-friendly

- Ansul Piranha – dual agent (wet + water mist) for solid fuel kitchens

- Turkey-engineered equivalents – CE & EN16282-6 certified, export-ready

💡 Downtime cost calculator: In Berlin, a bakery without suppression lost €9,800 in 4 days of closure. Insurance delayed payouts because the system wasn’t certified. Don’t risk it.

Integration with Turnkey Projects

Supporting systems must never be treated as “standalone.” At CKP, we align grease filtration, air balance, and suppression units with:

• BOQ matching & tender-ready documentation

• MEP coordination for ducting & utilities

• Consultant approval packs (CE, HACCP, ISO)

• DWG/BIM files for layout integration

📊 Comparison Snapshot

Feature | Grease Filters | Exhaust Units | Fire Suppression |

Core Function | Trap grease | Balance airflow | Stop fire instantly |

Safety Role | Reduce fire load | Improve hygiene & comfort | Protect life & property |

Compliance | CE, HACCP | CE, ISO, EN | UL 300, NFPA 96, EN |

Best Placement | Hoods & ducts | Rooftop / ceiling | Inside hoods & ducts |

💡 Why It Matters for Consultants & Operators

Ignoring these three elements often leads to:

• Failed fire audits & insurance claims denied.

• Staff complaints from heat, smoke, and noise.

• Costly duct cleaning & grease disposal.

With CKP’s Turkey-built supporting systems, contractors, consultants, and operators gain peace of mind, lower lifecycle costs, and smooth project approvals.

❓ FAQ – Supporting Equipment & Accessories

How often should grease filters be cleaned?

For heavy-use kitchens, every 1–2 weeks. In light cafés, monthly may be enough. Stainless units are dishwasher-safe.

Can make-up air units reduce energy bills?

Yes — by balancing exhaust with tempered supply, they cut HVAC load and staff fatigue.

Do fire suppression systems need water lines?

Not always. Wet chemical (R-102) systems don’t. Dual-agent systems like Piranha require water connections.

Are these systems compliant with international codes?

Yes — all systems are CE, UL300, NFPA 96, EN 16282-6 certified. We adapt specs per project location.

What’s the lead time for export projects?

Standard: 2–4 weeks. Custom or large-scale systems: 5–6 weeks with full CAD & certification packs.

💬 Real Projects & Client Testimonials – What Our Partners Say