“The Equipment Was Premium, But the Kitchen Still Failed.”

We hear this sentence more often than expected: “We invested in good equipment, but the kitchen is not working.”

Across hotel and resort projects in Africa, the Middle East, and Europe, the root cause is rarely the brand or the budget. In most cases, it is the commercial kitchen design layout itself. We seen this repeatedly in turnkey kitchen projects where even high-end, Turkey-built equipment could not compensate for poor zoning, weak workflow logic, or late MEP coordination.

As part of turnkey kitchen projects, layout planning is not a drawing exercise. It is a strategic project decision that directly affects food quality, staff productivity, energy consumption, and long-term operating cost. Consultants, kitchen designers, procurement managers, and facility teams all carry the consequences when layout decisions are rushed.

This guide explains how to plan a commercial kitchen design layout for hotels and resorts, based on real project execution experience and factory-direct, Turkey-made engineering practices used globally.

What Is a Commercial Kitchen Design Layout — and Why It Matters in Hotels

A commercial kitchen layout defines how food, people, equipment, utilities, and service flows interact in real operation — not just on paper.

In hotel kitchens, layout mistakes are expensive because:

- Service volumes are high and predictable

- Service windows cannot move

- Labor cost is fixed

- Post-opening renovation disrupts guest experience

Unlike standalone restaurant kitchens, hotel and resort kitchens must simultaneously support:

- Multiple outlets

- Banquet and event production

- Room service

- Central production kitchens

- Seasonal peak loads

We seen kitchens that passed consultant approval but failed during full occupancy because layout logic was never tested against real service flow.

Step 1: Start With Menu & Service Concept — Not Equipment

One of the most common errors in commercial kitchen design is starting with equipment lists instead of menu logic.

Before placing a single line on a layout, the project team must define:

- Buffet-driven vs à la carte service

- Daily vs seasonal banquet load

- Centralized vs outlet-based production

- Ratio of hot, cold, baked, and pre-prepared items

In turnkey kitchen projects, menu-to-layout alignment prevents overdesign and underutilization. We seen layouts collapse when pastry volume was underestimated or when central kitchens were forced to support à la carte outlets without proper zoning.

Step 2: Zoning — The Structural Backbone of Workflow

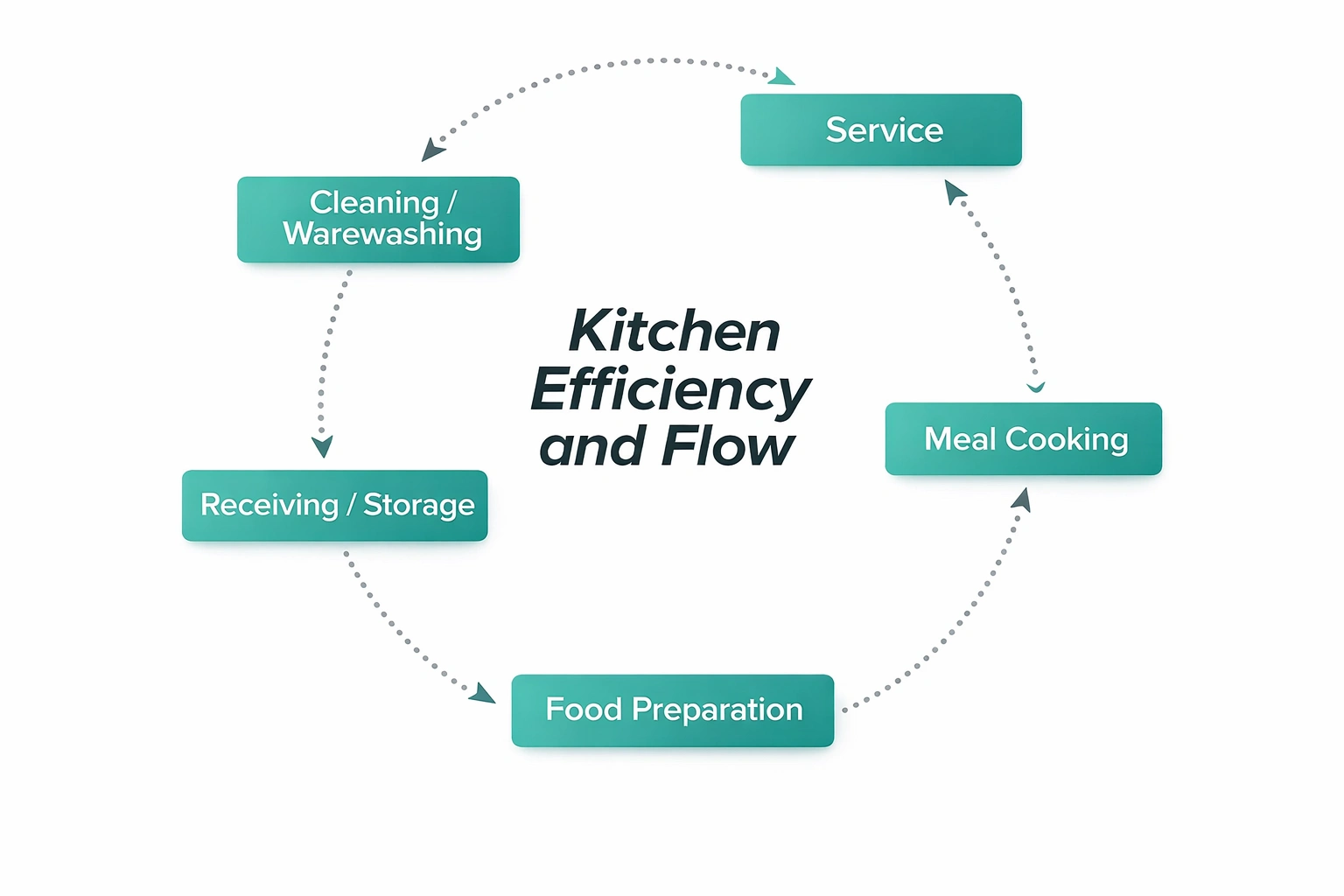

A professional commercial kitchen layout is built around functional zones, not equipment clusters.

Core zones typically include:

- Receiving and storage

- Cold preparation

- Hot kitchen

- Bakery and pastry

- Dishwashing and waste

- Service and dispatch

In resort kitchens, zoning must also consider distance and circulation. A technically perfect hot kitchen fails if service routes are long, crossed, or intersect guest pathways.

We seen in large African resort projects that poor zoning increased staff movement by 18–22% per shift, raising labor fatigue without increasing output.

Step 3: Workflow Optimization — Design for People, Not Machines

Workflow determines whether a kitchen feels controlled or chaotic during peak service.

Key workflow principles include:

- Linear movement without backtracking

- Strict separation of clean and dirty paths

- Logical prep-to-cook-to-serve sequencing

- No crossover between raw and cooked food

Consultants may draw elegant layouts, but workflow validation only happens through operational simulation. In turnkey projects, we physically walk the kitchen as if service has already started — this is where hidden issues appear.

Step 4: Layout + MEP Integration — The Most Critical Failure Point

A commercial kitchen layout is incomplete without MEP integration.

Layout decisions directly affect:

- Electrical load and phase balance

- Gas routing and pressure drops

- Water pressure and drainage slopes

- Hood positioning and exhaust capture

- HVAC heat recovery and comfort balance

We seen Middle East hotel projects where late layout changes after MEP freeze caused weeks of delay and significant variation cost. This is why MEP coordination must happen before layout approval, not during installation.

Step 5: Equipment Placement Is the Result — Not the Starting Point

In professional kitchen design, equipment selection comes after:

- Menu definition

- Zoning logic

- Workflow planning

- MEP alignment

When equipment is placed too early, layouts become rigid. Turkey-made equipment suppliers working in turnkey projects offer factory-direct dimensional flexibility, allowing size or configuration adjustments without redesigning the entire kitchen.

This flexibility is often missing when layouts are locked to imported equipment at concept stage.

Regional Project Scenarios — Why One Layout Never Fits All

Africa: Space Is Available, Infrastructure Is Not

Layouts must account for:

- Voltage fluctuation

- Limited drainage slopes

- Future expansion planning

Middle East: Peak Capacity Defines Design

Layouts must handle:

- High banquet loads

- Simultaneous outlet service

- Heavy HVAC demand

Europe: Retrofit Constraints Dominate

Layouts must work within:

- Existing structures

- Noise and vibration limits

- Strict energy regulations

We seen the same “standard layout” fail across regions because it ignored local operating realities.

Pre-Freeze Layout Control Checklist (Project-Safe)

Before approving any commercial kitchen layout:

- Menu volumes are validated

- Service routes are optimized

- MEP loads are calculated, not estimated

- Expansion zones are reserved

- Equipment maintenance access is planned

- HACCP flows are respected

- BOQ matches the final drawing

Skipping this step usually leads to redesign during installation — the most expensive phase to correct mistakes.

The Made in Turkey Advantage in Layout Planning

Turkey-built commercial kitchen solutions provide critical advantages during layout development:

- Faster drawing revisions

- Factory-direct customization

- Shorter lead times

- Stronger coordination between layout and fabrication

In turnkey kitchen projects, this allows consultants and procurement teams to finalize layouts without locking into inflexible systems too early.

Why Layout Planning Must Be Turnkey Thinking

Commercial kitchen layout sits at the intersection of:

- Consulting

- Engineering

- Procurement

- Installation

- Operations

Project-based kitchen contractors understand that layout decisions affect every downstream activity. The most successful hotel kitchens are designed as systems, not collections of equipment.

FAQ – Commercial Kitchen Design Layout for Hotels & Resorts

What is the best commercial kitchen layout for hotels and resorts?

The best layout is not a fixed template. It is designed around menu volume, service type, staff flow, and MEP capacity.

Why do commercial kitchen layouts fail after opening?

Most failures happen because workflow and MEP coordination were not validated under real operating conditions.

Should kitchen layout planning come before equipment selection?

Yes. In turnkey kitchen projects, layout planning always comes first.

How does commercial kitchen layout affect operating costs?

A well-planned layout can reduce operating costs by 15–20% over time.

When should a hotel consider a turnkey kitchen project?

When multiple outlets, banqueting, or central production are involved, turnkey coordination becomes critical.