“The Kitchen Looked Perfect, Until Service Started.”

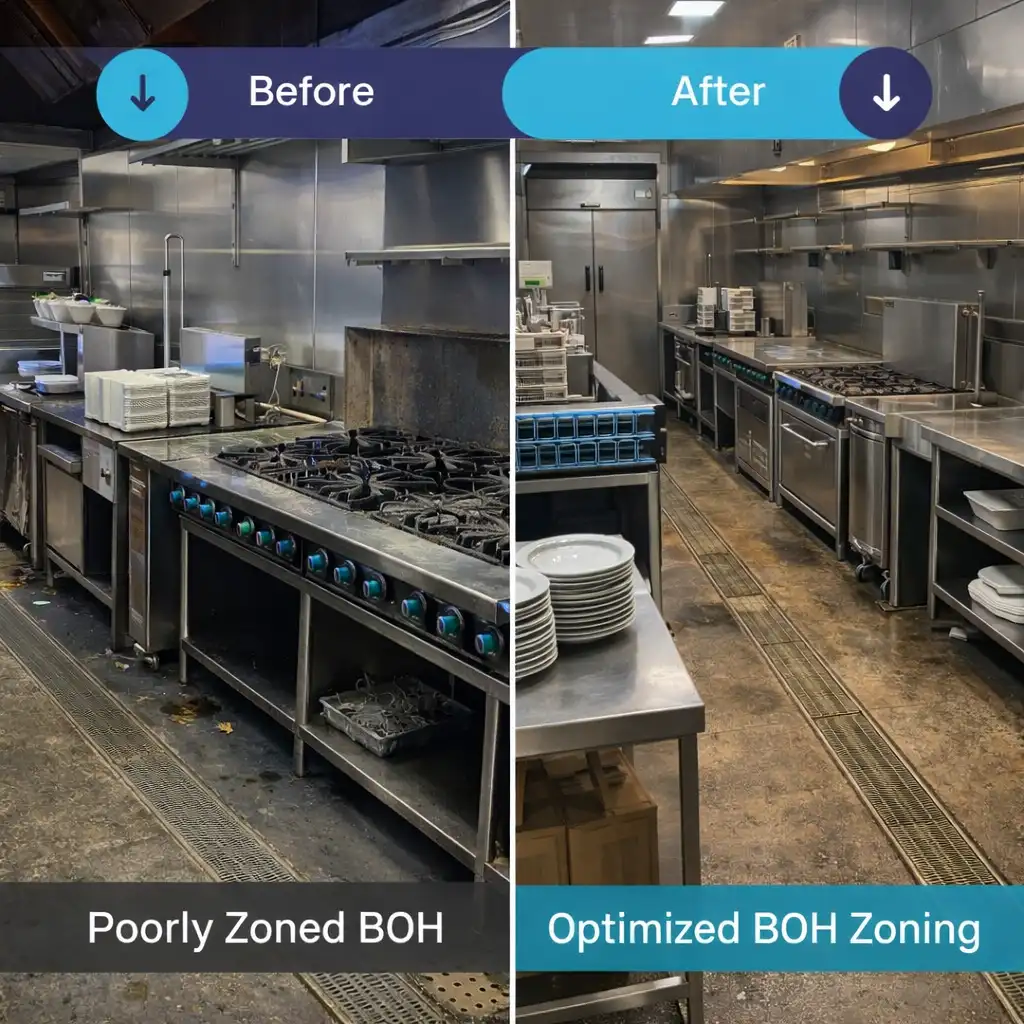

From our work on turnkey kitchen projects across Africa, the Middle East, and Europe, we’ve seen the same pattern repeat itself. The kitchen looks complete, equipment is installed, commissioning is signed — and yet, the first banquet service exposes the real problem. Not equipment. Not staffing. Back of House zoning.

In large central production kitchens and banquet-driven hotel operations, BOH zoning is not an architectural preference. It is an engineering decision that directly affects throughput, hygiene control, labor efficiency, and long-term operating cost. Across multiple projects, even Turkey-built, factory-direct equipment could not recover performance lost due to poor BOH logic.

This article explains how to zone BOH areas correctly in commercial kitchen design, with an analytic, engineering-driven perspective focused on central production and banquet kitchens.

What BOH Really Means in Commercial Kitchen Design

BOH Zoning vs Kitchen Layout – Why They Are Not the Same

Kitchen layout defines geometry — where walls, rooms, and equipment are placed. BOH zoning, however, defines operational logic — how food, staff, waste, and utilities move under pressure.

Many projects fail because layouts are visually correct, but zoning logic is never tested against real service scenarios. BOH zoning answers how the kitchen works, not just how it looks.

In hotel and resort kitchens, Back of House is not a single space. It is a system of interdependent zones that must operate under time pressure, hygiene rules, and fixed service windows.

BOH zoning governs:

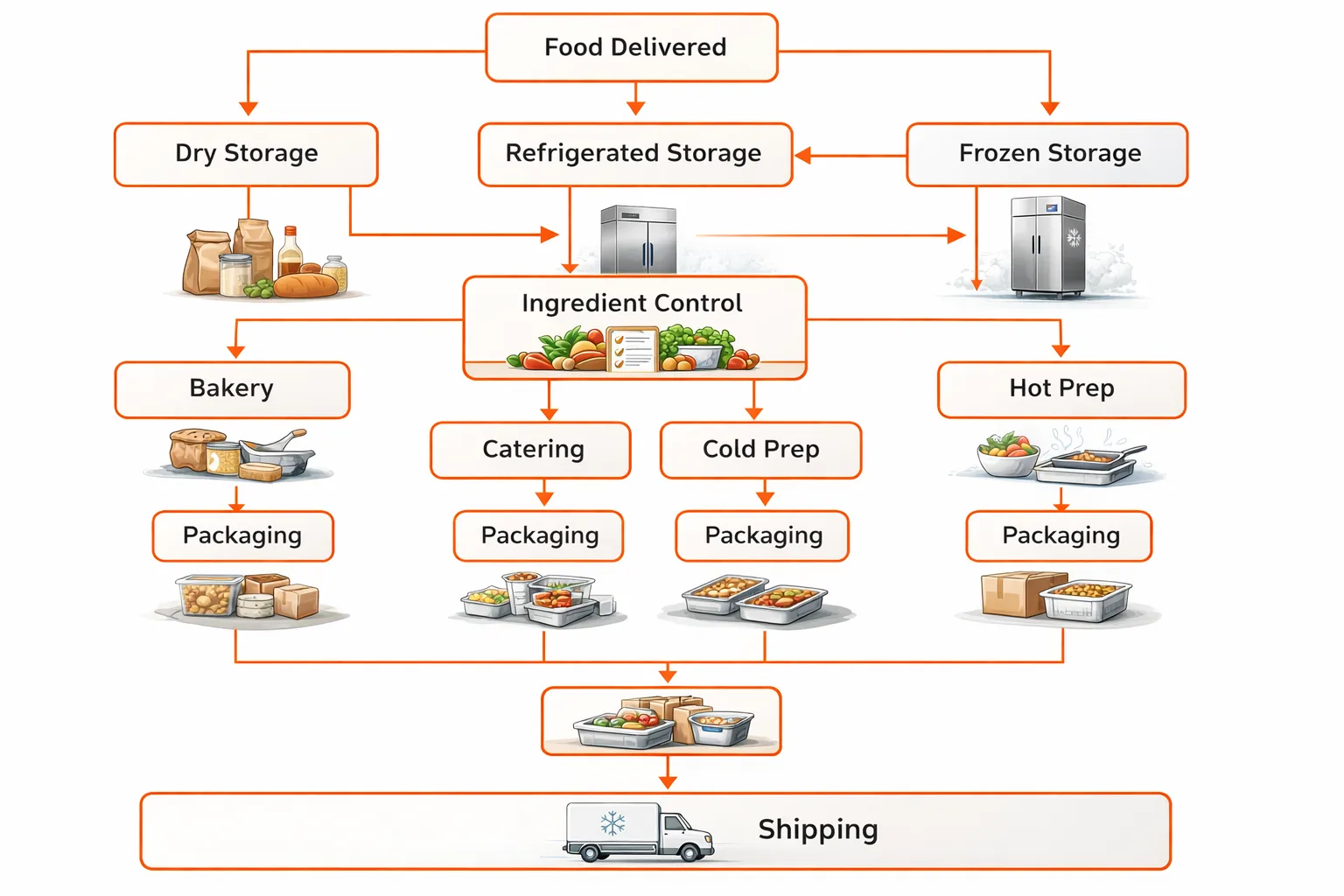

- Product flow from receiving to service

- Separation of clean and dirty circulation

- Staff movement under peak load

- HACCP compliance and cross-contamination control

- MEP load distribution and ventilation balance

Unlike front-of-house spaces, BOH mistakes are rarely visible on drawings — but they become painfully obvious during live service.

Why BOH Zoning Fails in Central Production & Banquet Kitchens

📊 BOH Zoning Impact – Measurable Operational Outcomes

Based on multi-region turnkey kitchen execution data, correct BOH zoning delivers measurable performance gains:

- Internal staff travel reduced by 15–25% through optimized circulation logic

- Service delays during banquet peaks reduced by up to 30% with separated dispatch and dishwashing flows

- Post-installation change orders reduced by 40–60% when BOH zoning is validated before MEP freeze

These gains are not theoretical. They directly translate into labor efficiency, energy stability, and predictable service output during peak hotel operations.

In central production environments, volume and simultaneity magnify every design error.

Common failure reasons include:

- Zoning copied from à la carte kitchens into batch-production systems

- Underestimated holding and staging areas for banquets

- Shared circulation between raw prep and finished food

- Dishwashing zones intersecting with service dispatch

In several banquet kitchens in Africa, poor BOH zoning increased internal travel distance by 20% per shift, directly impacting service speed without increasing output.

Core BOH Zones and Their Engineering Conflicts

BOH Zoning by Kitchen Type – Risk Comparison

Kitchen Type | Zoning Priority | Primary Risk if Mis-Zoned |

Central Production | Holding & staging | Congestion, batch delays |

Banquet Kitchens | Dishwashing & dispatch | Cross-flow, service bottlenecks |

À la Carte Outlets | Prep adjacency | Backtracking, staff fatigue |

Each kitchen type requires a different zoning logic. Applying a standard template across all concepts consistently leads to operational failure.

Receiving & Storage

Receiving is the first pressure point in BOH zoning. In central production kitchens, this zone must support simultaneous dry, chilled, and frozen intake without crossing prep paths.

Engineering risks:

- Insufficient buffer space during bulk deliveries

- Drainage conflicts with cold storage zones

- Inadequate separation between waste return and clean intake

Preparation Areas

Prep zones must be sized for peak batch production, not average daily use.

Key considerations:

- Dedicated raw protein prep with controlled drainage

- Vegetable prep isolated from hot zones

- Direct adjacency to cold storage, not cooking lines

Prep bottlenecks have repeatedly caused full banquet delays even when cooking capacity was sufficient.

Cooking & Central Production Lines

In banquet kitchens, cooking is rarely the bottleneck — staging and sequencing are.

BOH zoning must allow:

- Linear progression from prep → cook → hold

- Clear separation between bulk cooking and à la carte finishing

- Redundancy paths during peak service windows

Dishwashing & Waste Management

Dishwashing zones are among the most mis-zoned BOH areas.

Typical issues:

- Dirty return paths crossing service dispatch

- Undersized waste holding near banquet halls

- Ventilation imbalance causing odor migration

In Middle East resort projects, poor dishwashing zoning often triggered post-opening modifications — the most expensive phase to correct.

Staff Circulation & Support Areas

Staff movement is an engineering variable, not a behavioral one.

Effective BOH zoning minimizes:

- Cross-traffic between production teams

- Backtracking during service

- Congestion at shift change and peak dispatch

BOH Zoning + MEP + Workflow – The Critical Intersection

BOH zoning decisions directly define:

- Exhaust hood grouping and air balance

- Drainage slope continuity across zones

- Electrical load clustering

- Heat and noise distribution

In European retrofit projects, BOH zones designed without proper MEP coordination caused negative pressure in prep areas, pulling grease odors across clean zones.

In turnkey kitchen projects, BOH zoning must be validated against MEP logic before layout freeze — not after installation starts. This is also why early MEP coordination plays a decisive role in BOH zoning performance across large-scale hotel kitchens.

Regional BOH Zoning Scenarios

Africa – Space Is Available, Infrastructure Is Not

BOH zoning must account for:

- Voltage fluctuation tolerance

- Future expansion corridors

- Simplified circulation with minimal dependency on automation

Middle East – Banquet Peaks Define Everything

BOH zoning must support:

- Extreme peak loads within fixed time windows

- Large holding and plating zones

- High-capacity dishwashing with separated dirty flow

Europe – Retrofit and Regulation Driven

BOH zoning must adapt to:

- Existing structures

- Noise and emission limits

- Strict energy and hygiene regulations

Standard zoning templates fail when regional operating realities are ignored.

What Happens When BOH Zoning Is Ignored After Opening?

When BOH zoning issues are discovered after opening, consequences escalate quickly:

- First banquet services experience delays despite sufficient cooking capacity

- Emergency post-opening modifications disrupt guest experience

- Rework costs increase exponentially due to finished floors, ceilings, and MEP systems

In large hotel projects, correcting BOH zoning after handover can cost 5–8x more than resolving the same issue during design coordination.

Pre-Freeze BOH Zoning Checklist (Engineering-Controlled)

Before approving BOH zoning in a commercial kitchen project:

- Central production volumes are validated

- Banquet peak scenarios are simulated

- Clean and dirty flows are physically separated

- MEP loads match zone intensity

- Holding and staging areas are sized for peak use

- Maintenance access is protected

- BOQ aligns with final zoning

Skipping this control step often leads to redesign during installation — the most expensive correction phase.

The Made in Turkey Advantage in BOH Flexibility

Turkey-built commercial kitchen systems provide critical zoning flexibility in turnkey projects:

- Factory-direct customization of dimensions

- Faster layout revisions during coordination

- Shorter lead times for zone-specific fabrication

- Better alignment between equipment and BOH logic

This flexibility allows engineers to refine BOH zoning without locking the project into rigid systems too early.

Who Should Be Involved in BOH Zoning Decisions?

Effective BOH zoning requires early input from:

- Hotel owners defining long-term operating strategy

- Procurement managers balancing BOQ accuracy and flexibility

- Kitchen consultants shaping production logic

- Turnkey contractors coordinating layout, MEP, and installation as one system

When BOH zoning is left to a single discipline, blind spots emerge. Successful projects treat zoning as a shared engineering responsibility.

Why BOH Zoning Is a Turnkey Engineering Decision

BOH zoning sits at the intersection of:

- Kitchen design

- Production engineering

- MEP coordination

- Procurement strategy

- Installation sequencing

Project-based kitchen contractors understand that BOH decisions cannot be corrected cheaply after handover. The most successful central production kitchens are engineered as systems, not room layouts.

FAQ – BOH Zoning in Commercial Kitchen Design

What is the biggest BOH zoning mistake in banquet kitchens?

Underestimating staging, holding, and circulation during peak banquet service.

Should BOH zoning be finalized before equipment selection?

Yes. Equipment must adapt to zoning logic, not dictate it.

How does BOH zoning affect HACCP compliance?

Incorrect zoning often causes raw and cooked flow intersections, leading to non-compliance.

Can BOH zoning reduce operating cost?

Yes. Proper zoning can reduce labor movement and energy loss by 15–20%.

Why do turnkey projects perform better in BOH zoning?

Because layout, MEP, equipment, and installation are coordinated as one system.